Top 10 Industrial Automation Software Solutions for Streamlining Production

In the rapidly evolving world of manufacturing, the importance of industrial automation software has never been more pronounced. As industries strive to enhance efficiency and reduce operational costs, these software solutions provide the backbone for modern production environments. Dr. Emily Carter, a renowned expert in industrial automation, emphasizes, “The adoption of advanced industrial automation software is crucial for businesses aiming to stay competitive in a fast-paced market.” This sentiment reflects a growing recognition of technology's transformative potential in streamlining production processes and enhancing productivity.

The integration of industrial automation software enables companies to optimize their workflows, minimize errors, and increase output while maintaining quality standards. By leveraging real-time data analytics and intelligent automation, organizations can identify bottlenecks, predict maintenance needs, and make informed decisions that drive growth. As the landscape of manufacturing continues to shift, it is essential for businesses to explore innovative software solutions that not only meet current demands but also set the stage for future advancements.

In this article, we will delve into the top 10 industrial automation software solutions that are defining the future of production. By highlighting their key features and benefits, we aim to provide insights that can help manufacturers make informed choices about embracing automation in their operations. As we navigate this crucial aspect of industry evolution, it becomes clear that investing in the right industrial automation software is not just a choice—it's a necessity for sustainable success.

Overview of Industrial Automation Software Solutions

Industrial automation software solutions

are pivotal in optimizing production processes across various industries. These solutions facilitate the integration of hardware and software systems, enabling real-time monitoring and control of manufacturing operations. By streamlining tasks such as machine control, data collection, and process automation, businesses can achieve greater efficiency and reduce operational costs. The versatility of these software applications allows for customization to meet specific needs, whether in discrete manufacturing or process industries.

One of the key benefits of industrial automation software is its ability to provide actionable insights through data analytics. By harnessing data from machinery and production lines, these systems enable managers to make informed decisions that enhance productivity and quality. Additionally, many solutions offer user-friendly interfaces, empowering operators to easily navigate and control complex processes.

As industries continue to evolve with the advent of Industry 4.0,

the importance of automation software in facilitating seamless communication between devices and systems cannot be overstated. This shift not only drives innovation but also positions companies for sustainable growth in an increasingly competitive landscape.

Key Features to Look for in Automation Software

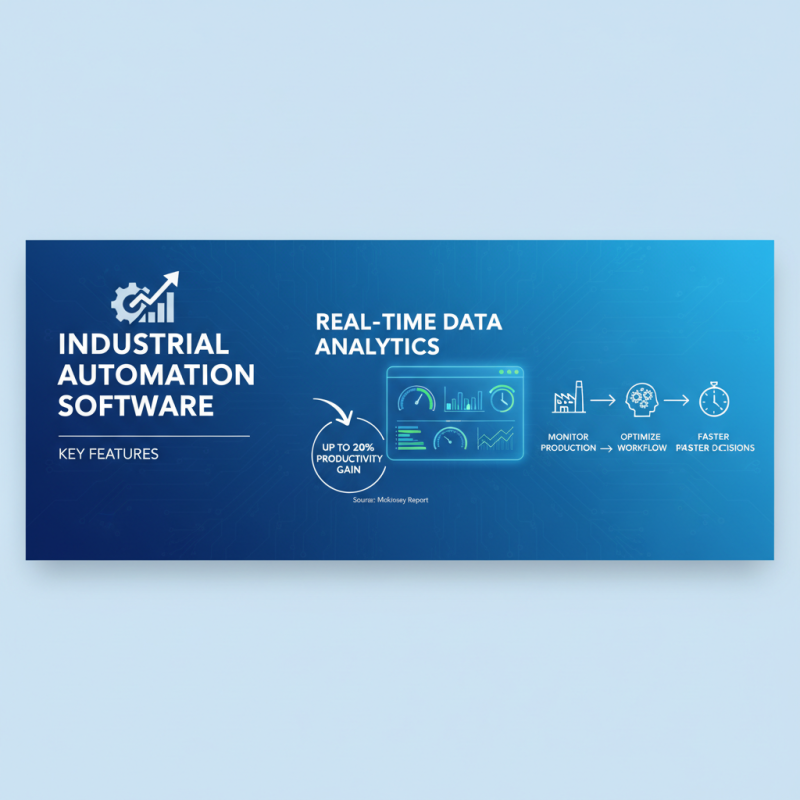

When selecting industrial automation software, there are several key features that can significantly enhance production efficiency and streamline operations. One vital aspect to look out for is real-time data analytics. According to a recent report by McKinsey, companies that leverage real-time analytics can increase productivity by up to 20%. This feature enables manufacturers to monitor production metrics instantaneously and make data-driven decisions that optimize the workflow.

Another essential element is seamless integration capabilities. Automation software should easily integrate with existing systems and machinery to ensure a smooth transition and minimal downtime. In fact, a survey conducted by Deloitte revealed that 65% of organizations reported significant improvements in operational efficiency when their automation systems were effectively integrated. This functionality enables teams to harness the full potential of their equipment and makes adaptability to changes in production demands much easier.

**Tips:** When choosing automation software, prioritize solutions that offer user-friendly interfaces and robust customer support. This ensures that your team can efficiently utilize the software without extensive training. Additionally, consider looking for platforms that provide cloud-based functionalities, as these can offer flexibility and scalability as your production needs evolve.

Top 10 Industrial Automation Software Solutions Reviewed

Industrial automation software plays a crucial role in enhancing the efficiency and productivity of manufacturing processes. By integrating technologies such as robotics, machine learning, and data analytics, these solutions allow companies to streamline operations, minimize downtime, and enhance product quality. The review of the top industrial automation software solutions highlights key features that can improve production workflows, such as real-time monitoring, advanced reporting capabilities, and seamless integration with existing systems. These functionalities empower businesses to make informed decisions, adapt quickly to market changes, and optimize resource allocation.

Moreover, effective automation software not only facilitates better communication between machines and operators but also helps in identifying bottlenecks and areas for improvement. Many of these solutions offer customizable dashboards that provide user-friendly insights into production metrics, enabling teams to react promptly to any issues that may arise. As industries continue to evolve, the integration of robust software solutions will be essential for businesses aiming to maintain a competitive edge while achieving higher levels of efficiency and reliability in their manufacturing processes.

Top 10 Industrial Automation Software Solutions for Streamlining Production

Comparative Analysis of Popular Automation Tools

In the rapidly evolving landscape of industrial automation, companies are increasingly reliant on software solutions to optimize production processes and enhance operational efficiency. A recent report by MarketsandMarkets indicates that the global industrial automation market is projected to grow from $202.2 billion in 2021 to $295.7 billion by 2026, showcasing the significant shift towards automation technologies. The adoption of automation tools is crucial for organizations seeking to reduce operational costs and improve productivity.

A comparative analysis of the leading automation tools reveals several key features that can streamline production. Firstly, the integration capabilities with existing systems are essential; those solutions that support interoperability can significantly reduce downtime and implementation costs.

Additionally, user experience is a vital factor, with intuitive interfaces allowing for quicker training and reduced reliance on specialized personnel. According to a report from McKinsey & Company, companies that prioritized user-friendly software saw a 20% increase in adoption rates among employees, which directly correlated to improved production efficiency. Evaluating these attributes is critical for organizations aiming to select the most effective automation software to meet their specific operational needs.

Benefits of Implementing Automation Software in Production

Implementing automation software in industrial production offers numerous benefits that can significantly enhance operational efficiency and reduce costs. According to a report by McKinsey, automation in manufacturing can increase productivity by 20 to 30 percent, enabling companies to produce more with the same amount of resources. This kind of software streamlines processes by minimizing manual intervention, thus reducing human error and refining accuracy in production lines.

Moreover, automation software provides real-time data analytics that empowers organizations to make informed decisions swiftly. According to a study by IDC, companies that leverage real-time analytics report a 10% increase in overall operational efficiency. By automating routine tasks, such as inventory management and quality control, manufacturers can allocate human resources to more strategic roles, ultimately driving innovation and growth. Enhanced predictability in operations leads to more reliable supply chains, further optimizing production flow and meeting market demands efficiently.

Related Posts

-

Understanding Control Systems Automation for Enhanced Efficiency and Performance

-

How to Choose the Right Industrial Automation Software for Your Business

-

2025 Top 10 Automation Equipment Trends Driving Industry Growth and Efficiency

-

Top Benefits of Production Automation for Modern Manufacturing Efficiency

-

2025 How to Choose the Best Manufacturing Automation Software for Your Business

-

How to Build and Optimize Automatic Systems for Maximum Efficiency