2025 Top 10 Automation Equipment Trends Driving Industry Growth and Efficiency

In the rapidly evolving landscape of the manufacturing sector, the role of automation equipment has become increasingly pivotal. As industries strive for greater efficiency and higher productivity, the latest forecasts from MarketsandMarkets suggest that the global automation equipment market is expected to reach over $100 billion by 2025, growing at a CAGR of approximately 9.2%. This significant growth is driven by advancements in technology, the need for improved operational efficiency, and the rising demand for customized production processes.

Expert insights further emphasize the importance of embracing these innovations. John Smith, a leading authority in industrial automation, remarked, "The future success of manufacturing hinges on the ability to integrate smart automation equipment into existing processes, enabling businesses to not only enhance productivity but also adapt swiftly to market changes." As we look toward 2025, identifying the top trends within the automation equipment sector is crucial for companies aiming to remain competitive and leverage the full potential of automation technologies. By understanding these trends, businesses can align their strategies to drive growth and efficiency in an increasingly automated world.

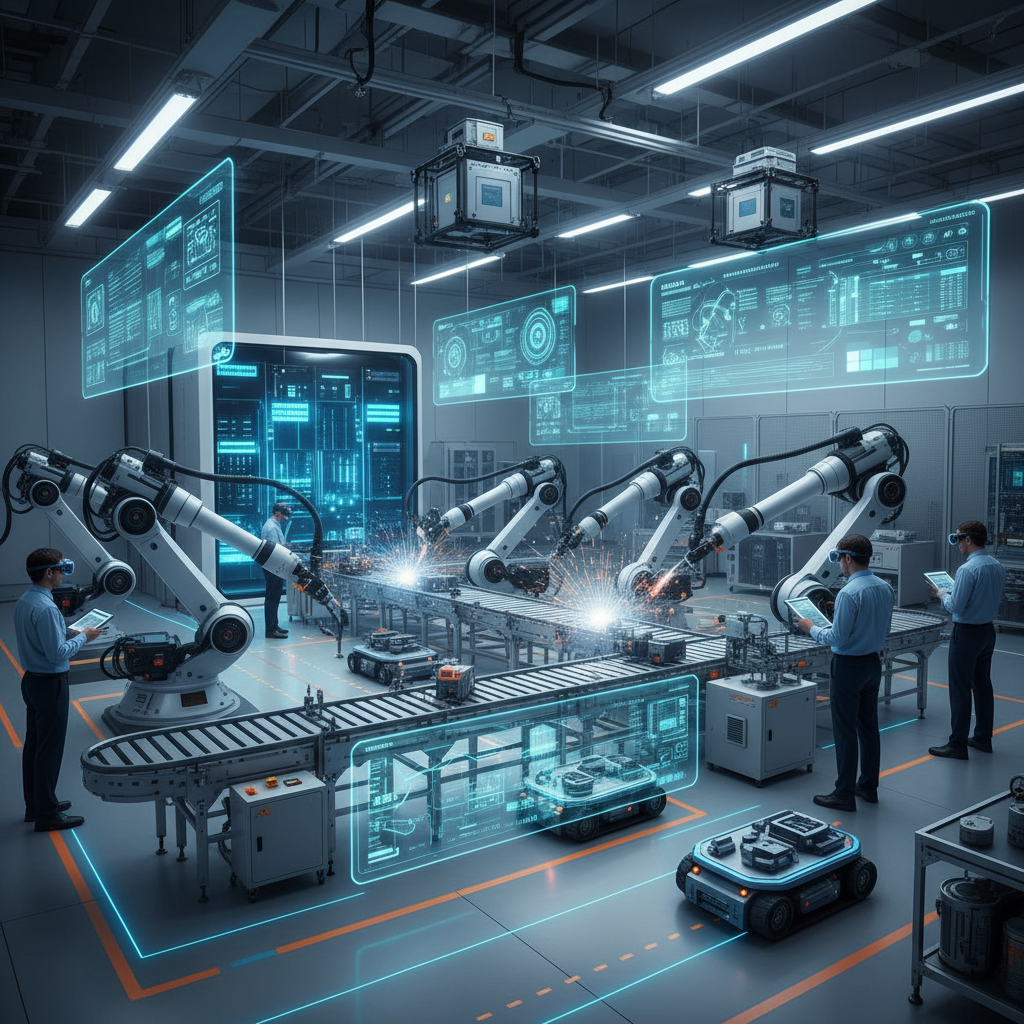

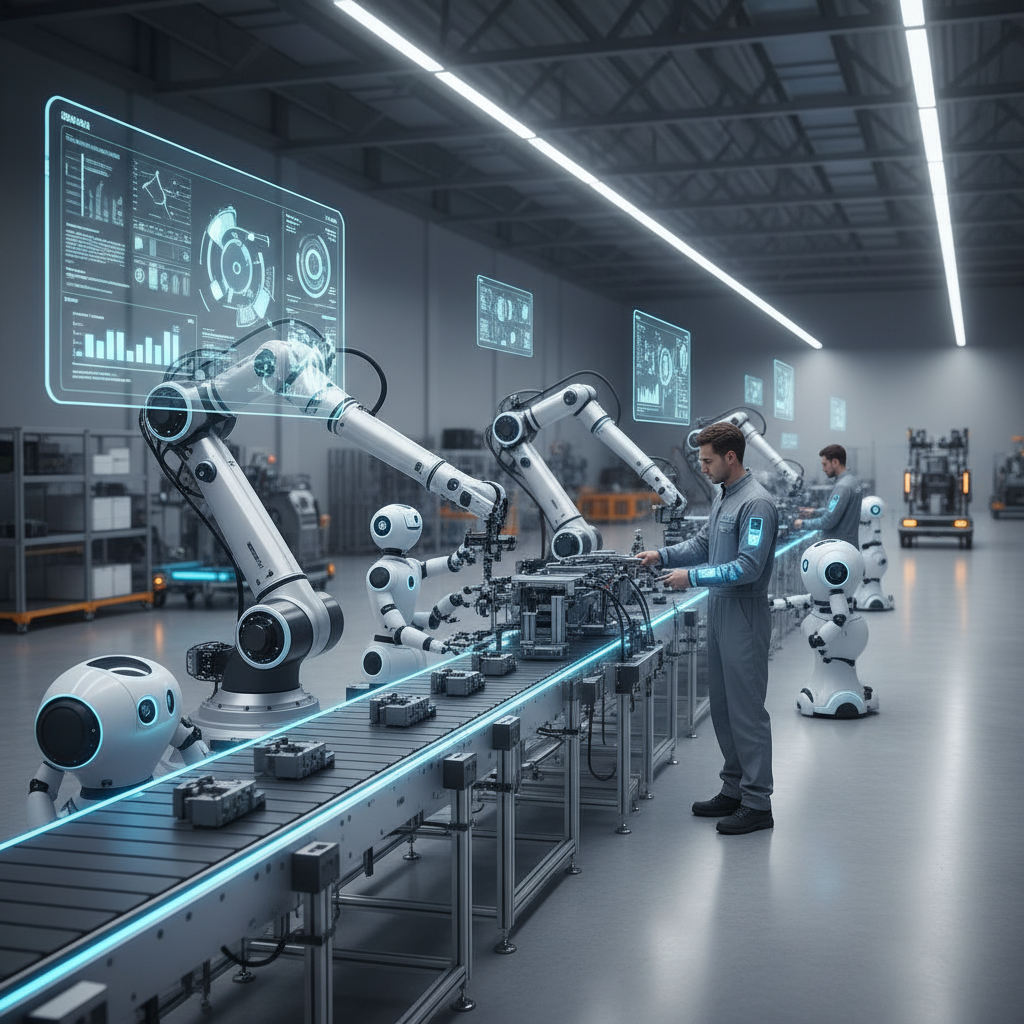

Emerging Robotics Technologies Revolutionizing Production Lines

Emerging robotics technologies are set to transform production lines in unprecedented ways. As industries increasingly adopt automation, advanced robotics systems are being integrated to enhance operational efficiency and precision. Collaborative robots, or cobots, are a prime example of this revolution, designed to work alongside human operators safely. These systems not only optimize workflows but also reduce the risk of injury, making them essential in manufacturing environments.

Additionally, artificial intelligence and machine learning are being incorporated into robotic systems, enabling them to adapt to fluctuating production demands. This adaptability allows for real-time decision-making, significantly improving throughput and minimizing downtime. With innovations like autonomous mobile robots (AMRs) and robotic arms equipped with advanced sensors, companies can streamline logistics, handling materials with extreme accuracy and speed. As these technologies continue to evolve, they will further drive efficiency and growth across various industries, positioning robotics at the forefront of the next industrial revolution.

The Role of AI and Machine Learning in Automation Advancement

The integration of artificial intelligence (AI) and machine learning into automation equipment is transforming the manufacturing landscape. According to a recent report by McKinsey, businesses that have adopted AI-driven automation have seen productivity increases of up to 40%. This surge in efficiency is largely attributed to AI's ability to analyze vast amounts of data in real-time, supporting predictive maintenance and optimizing workflow. By harnessing these technologies, industries are not only reducing operational costs but also enhancing product quality and consistency.

As we look towards 2025, the role of AI in automation will only intensify. A study by Gartner forecasts that by 2024, 75% of organizations will have shifted from piloting to operationalizing AI, a move that will fundamentally enhance automation processes. Machine learning algorithms are particularly adept at identifying patterns in production line data, allowing for quicker adjustments and fostering a proactive approach to both equipment maintenance and quality control. This trend is setting the stage for smarter factories that can adapt to changing demands with agility and efficiency, thus driving significant industry growth as more companies embrace these cutting-edge technologies.

Sustainability in Automation: Eco-Friendly Equipment Innovations

As industries increasingly recognize the importance of sustainability, eco-friendly innovations in automation equipment are becoming a pivotal focus. The integration of green technologies is revolutionizing traditional manufacturing processes. Companies are now leveraging automation solutions that not only enhance productivity but also minimize environmental footprints. For instance, the development of energy-efficient robots and machinery equipped with advanced sensors has led to significant reductions in power consumption. Moreover, these innovations are designed to utilize recyclable materials, further contributing to a circular economy.

Additionally, software advancements in automation play a crucial role in enhancing sustainability. Intelligent systems can now optimize production schedules and supply chains, drastically reducing waste and excessive resource usage. The rise of artificial intelligence and machine learning enables automated processes to become more adaptive, improving operational efficiency while ensuring lower emissions. By prioritizing eco-friendly innovations, the automation industry is not only driving growth but also setting a new standard for sustainable practices across various sectors, paving the way for a greener future.

Integration of IoT in Automation: Connecting Machines for Efficiency

The integration of the Internet of Things (IoT) in automation is revolutionizing the industry by connecting machines and enhancing operational efficiency. This trend allows for real-time data collection and analysis, enabling industries to track performance, predict maintenance needs, and optimize production processes. By creating a seamless network of interconnected devices, manufacturers can respond to changes in demand swiftly and effectively, ensuring minimal downtime and maximum productivity.

**Tip:** Start by assessing your current automation systems and determine which machines would benefit the most from IoT integration. Prioritizing devices that can offer the highest return on investment will streamline your transition into smarter automation.

Moreover, IoT-enabled automation fosters improved communication between devices, leading to enhanced coordination across the supply chain. With intelligent systems sharing data, companies can better forecast supply needs, reducing excess inventory and cutting costs. This interconnected framework not only elevates efficiency but also supports sustainable practices by minimizing waste.

**Tip:** Consider participating in training sessions that focus on IoT technologies and their applications in automation. Empowering your team with knowledge will ensure that your organization is well-prepared to leverage these advancements effectively.

2025 Top 10 Automation Equipment Trends Driving Industry Growth and Efficiency

This chart illustrates the projected growth in the integration of IoT in automation equipment trends from 2023 to 2025.

Customizable Automation Solutions for Diverse Industry Needs

The landscape of automation equipment is rapidly evolving, and the demand for customizable solutions has never been higher. As industries strive for greater efficiency, businesses are recognizing the need for systems that can be tailored to specific operational requirements. Customizable automation solutions allow organizations to optimize workflows, reduce downtime, and improve productivity by adapting equipment to unique process demands, ensuring that each installation maximizes performance.

In 2025, flexibility and adaptability in automation technology will dominate industry trends, as manufacturers seek to integrate smart technologies that can be adjusted on-the-fly. This shift not only enhances operational efficiency but also enables companies to respond swiftly to changing market conditions. Customizable automation allows for seamless integration with existing systems, facilitating a smoother transition into more advanced manufacturing practices. As industries become more diverse and complex, the ability to customize automation solutions will be a key driver of growth and innovation, positioning businesses to thrive in a competitive landscape.