Top Benefits of Production Automation for Modern Manufacturing Efficiency

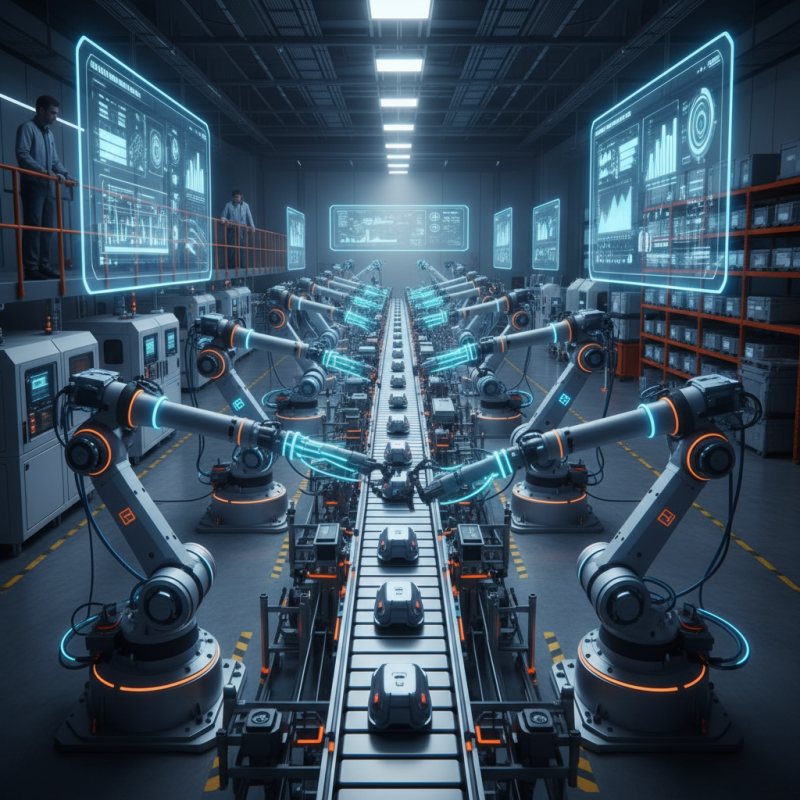

In the rapidly evolving landscape of modern manufacturing, the adoption of production automation has emerged as a critical driver of operational efficiency and competitiveness. According to a report by the International Federation of Robotics, global sales of industrial robots reached a record high of 384,000 units in 2020, representing a 12% increase compared to the previous year. This surge in automation adoption highlights the industry's recognition of the significant advantages that production automation can deliver, including enhanced productivity, improved quality, and reduced operational costs.

Furthermore, a study published by McKinsey & Company predicts that by 2030, up to 375 million workers worldwide may need to transition to different occupations due to advancements in automation technologies. This shift not only emphasizes the need for manufacturing sectors to embrace production automation but also underlines the necessity for organizations to adapt to these technological changes to remain relevant. By implementing automated processes, manufacturers can streamline operations, minimize human error, and allocate resources more effectively, thereby positioning themselves for sustained growth in an increasingly competitive global market.

As we delve into the top benefits of production automation, it becomes evident that this technological evolution is not merely a trend, but a fundamental transformation that is reshaping the future of manufacturing. Embracing production automation is crucial for companies aiming to enhance efficiency, optimize workflow, and ultimately drive innovation in their manufacturing processes.

Key Advantages of Production Automation in Modern Manufacturing

Production automation has become a pivotal element in enhancing manufacturing efficiency in today’s competitive landscape. The integration of advanced automation technologies can lead to significant reductions in operational costs. According to a report by the International Federation of Robotics, companies that fully implement automation can see productivity increases of up to 30% and a corresponding reduction in labor costs by around 20%. This shift not only streamlines operational workflows but also allows human workers to focus on more complex tasks, thereby improving job satisfaction and reducing turnover rates.

Additionally, production automation enhances consistency and quality in manufacturing processes. The Manufacturing Institute reports that automation can reduce manufacturing defects by as much as 50%, significantly improving product quality and customer satisfaction. This precision is critical in industries such as automotive and electronics, where even minor deviations can lead to costly recalls. Furthermore, automated systems can operate 24/7, enabling manufacturers to meet increasing demand without compromising on quality or efficiency. Thus, the adoption of production automation emerges as a strategic advantage in maintaining competitiveness and driving innovation in modern manufacturing.

Top Benefits of Production Automation for Modern Manufacturing Efficiency

| Benefit | Description | Impact on Efficiency |

|---|---|---|

| Increased Production Speed | Automation streamlines processes, allowing for faster production cycles. | A 20-30% increase in output per hour. |

| Reduced Labor Costs | Fewer manual interventions reduce the need for large labor forces. | Cost savings of up to 25% in labor expenses. |

| Improved Product Quality | Automation minimizes human error, leading to higher consistency in quality. | Reduction in defects by 15-20%. |

| Enhanced Flexibility | Automated systems can be easily reconfigured for different products. | Quick adaptation to market changes, reducing downtime. |

| Data-Driven Insights | Automation provides real-time data analytics for better decision-making. | Improved operational strategies leading to enhanced performance. |

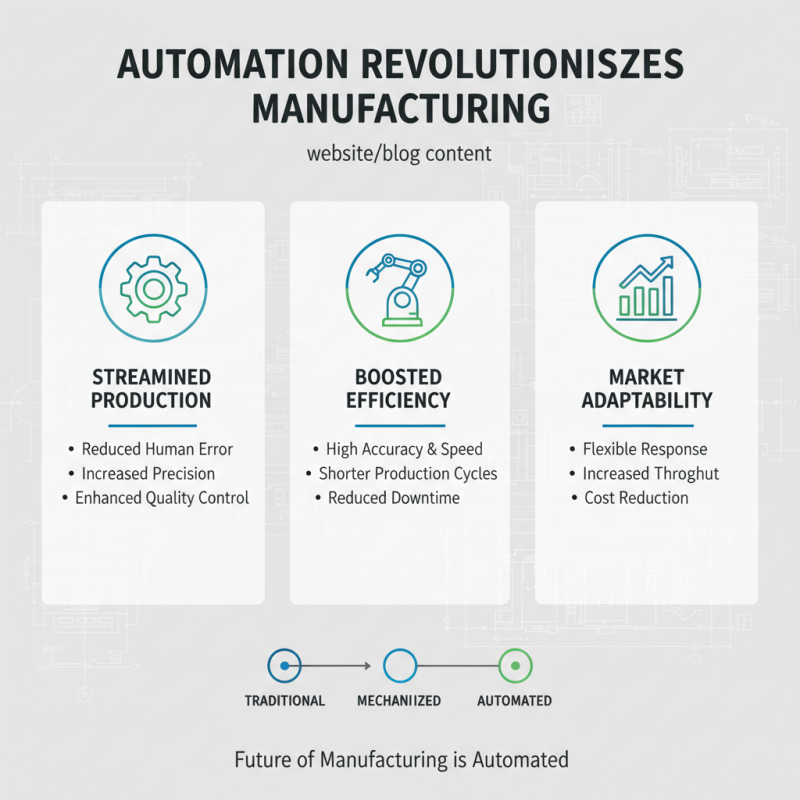

Streamlining Production Processes Through Automated Systems

Automation has revolutionized modern manufacturing, allowing companies to streamline production processes in unprecedented ways. By implementing automated systems, manufacturers can reduce human error, increase precision, and enhance overall quality control. Automated machines and robotics can perform repetitive tasks with high accuracy and speed, resulting in shorter production cycles and decreased downtime. This not only boosts efficiency but also enables manufacturers to respond more flexibly to market demands.

Moreover, the integration of automated systems into production lines helps in optimizing resource management. Automated processes can monitor and adjust inputs in real-time, ensuring that materials are utilized efficiently and waste is minimized. Advanced data analytics further aids in identifying bottlenecks and inefficiencies within the production workflow, allowing for continuous improvement. As a result, manufacturers are equipped to produce higher volumes with lower costs, ultimately enhancing their competitive edge in the market. This shift towards automation is a crucial step for businesses aiming to thrive in today's fast-paced industrial landscape.

Enhancing Precision and Quality Control with Automation Technology

Automation technology has revolutionized modern manufacturing by significantly enhancing precision and quality control. According to a report by the International Society of Automation, companies that implement automated systems can achieve a 25% increase in overall product quality and a 30% reduction in defect rates. This transformation allows manufacturers to maintain rigorous quality standards while streamlining their operations. By relying on advanced technologies such as robotics and AI-driven analytics, businesses can create products that consistently meet or exceed customer expectations.

To maximize the benefits of automation, manufacturers should focus on integrating real-time monitoring systems. These systems enable operators to track production metrics continuously, ensuring that any deviations from quality standards are detected and corrected instantly. Additionally, the use of predictive maintenance powered by AI can minimize downtime by forecasting when machinery will require maintenance, thus maintaining manufacturing continuity and quality.

Tips: Investing in staff training for using automation tools effectively is crucial. Empowering employees with the right skills ensures that any technology implemented is utilized to its fullest potential. Furthermore, regularly reviewing and updating quality control protocols in line with automation advancements can help manufacturers stay competitive and responsive to market demands.

Reducing Operational Costs and Increasing Profitability via Automation

In the realm of modern manufacturing, production automation emerges as a pivotal force in driving operational efficiency and enhancing profitability. According to a report by McKinsey, businesses that implement automation technologies can reduce labor costs by 20% to 30%, which significantly contributes to overall operational cost reduction. By minimizing the reliance on manual labor, manufacturers can not only streamline processes but also redirect resources towards strategic initiatives that foster growth and innovation.

Moreover, automation significantly boosts productivity levels, contributing to increased profitability. The same McKinsey report highlights that companies utilizing advanced automation can improve production output by up to 40%. This increase in efficiency allows manufacturers to respond more rapidly to market demands and fluctuations, ultimately gaining a competitive edge. Additionally, a study from the Boston Consulting Group indicates that companies with high levels of automation can achieve profit margins substantially above the industry average, emphasizing the correlation between automation investment and financial performance. By embracing these technologies, manufacturers position themselves for sustainable growth and heightened profitability in an increasingly competitive landscape.

Top Benefits of Production Automation for Modern Manufacturing Efficiency

Improving Workforce Productivity and Safety in Manufacturing Environments

Production automation plays a pivotal role in modern manufacturing by significantly enhancing workforce productivity and safety in various environments. By integrating automated systems and robotics into manufacturing processes, companies are able to streamline operations, reduce manual labor, and minimize human error. Automation allows workers to focus on higher-value tasks, enabling them to utilize their skills effectively while machines handle repetitive or hazardous duties. This shift not only increases overall output but also contributes to a more engaged and skilled workforce, as employees can concentrate on roles that require critical thinking and problem-solving.

Safety is another critical aspect improved by production automation. Automated systems can take on dangerous tasks, such as heavy lifting, handling toxic materials, and performing maintenance in hazardous environments. By reducing the need for workers to participate directly in risky activities, companies can significantly lower the incidence of workplace accidents and injuries. Furthermore, automated safety protocols can be implemented more efficiently than human-managed processes, ensuring that safety standards are consistently adhered to. As a result, a safer manufacturing environment fosters a culture of well-being, leading to lower absenteeism rates and higher morale among employees.

Related Posts

-

2025 How to Choose the Best Manufacturing Automation Software for Your Business

-

How to Choose the Right Industrial Automation Software for Your Business

-

Top Automation Control Trends to Watch in 2025 for Enhanced Efficiency

-

Understanding Control Systems Automation for Enhanced Efficiency and Performance

-

How to Build and Optimize Automatic Systems for Maximum Efficiency

-

Understanding Control Systems Automation Types and Their Applications