Top Industrial Automation Solutions to Improve Efficiency and Productivity

In today's rapidly evolving industrial landscape, the pursuit of efficiency and productivity has become paramount for organizations aiming to maintain a competitive edge. One of the most effective ways to achieve these goals is through the implementation of innovative industrial automation solutions. These solutions not only streamline operations but also reduce human error, enhance safety, and optimize resource management. As industries embrace the transformative capabilities of automation, they witness a significant shift in their operational dynamics, translating to faster production times and improved product quality.

Industrial automation solutions encompass a wide range of technologies and methodologies that facilitate the automation of manufacturing processes, equipment, and systems. By leveraging advanced robotics, artificial intelligence, and data analytics, businesses can create highly efficient workflows and minimize downtime. Furthermore, the integration of smart technologies enables real-time monitoring and predictive maintenance, ensuring that operations run smoothly and efficiently. As we explore the top industrial automation solutions, it becomes clear that these innovations play a crucial role in fostering a future where industries are not only more productive but also more sustainable and responsive to market demands.

Top Industrial Automation Solutions to Improve Efficiency and Productivity

In today's competitive landscape, leveraging industrial automation solutions is essential for enhancing efficiency and productivity across various sectors. According to a report by McKinsey, companies that adopt advanced automation technologies can improve their operational productivity by up to 20-30%. Automation not only streamlines processes but also reduces human error, leading to more consistent and reliable outputs. The integration of robotics and intelligent systems in manufacturing processes has shown significant reductions in cycle times and labor costs, promoting a more agile production environment.

Moreover, the adoption of the Industrial Internet of Things (IIoT) has transformed traditional manufacturing into smart factories, allowing for real-time data analysis and predictive maintenance. Research from Deloitte suggests that organizations implementing IIoT solutions could achieve a productivity increase of 10-20% over five years. By analyzing operational data, companies gain valuable insights that enable them to optimize workflows, minimize downtime, and enhance decision-making processes, thereby fostering a culture of continuous improvement and innovation.

Investing in automation technologies is no longer a luxury but a necessity for companies aiming to stay ahead in a rapidly evolving market. As firms increasingly focus on digital transformation, those that successfully integrate advanced automation solutions are likely to see substantial gains in productivity and overall operational efficiency, positioning themselves for long-term success in a competitive economy.

Top Industrial Automation Solutions to Improve Efficiency and Productivity

This chart illustrates the effectiveness of various industrial automation solutions in enhancing operational efficiency and productivity across different industries. The data represents the percentage improvement in productivity achieved through the adoption of these solutions.

Understanding the Basics of Industrial Automation and Its Impact on Efficiency

Industrial automation has emerged as a critical driver for enhancing operational efficiency and productivity across various sectors. By integrating advanced technologies such as robotics, artificial intelligence, and the Internet of Things (IoT), industries can reduce human error, increase process accuracy, and optimize resource allocation. According to a report by McKinsey, companies that implement automation can boost productivity by up to 30% and significantly lower operational costs, highlighting the profound impact of these technologies.

Understanding the basics of industrial automation is essential for organizations looking to leverage its potential. Automation systems can streamline workflows, from production lines to supply chain management, leading to quicker turnaround times. A study from the International Federation of Robotics indicates that global industrial robot installations are expected to reach 4 million units by 2025, reinforcing the trend towards automation as a standard in modern manufacturing. This wave of technological advancement enables businesses to adapt to changing market demands while maintaining a competitive edge.

Tips: Organizations should start by identifying key processes that are repetitive or prone to errors, as these are prime candidates for automation. Additionally, investing in employee training will ensure that teams can effectively manage and coexist with automated systems, ultimately leading to a seamless transition and increased overall productivity. Embracing a culture of continuous improvement will also help businesses stay ahead in this rapidly evolving technology landscape.

Key Technologies Driving Industrial Automation: AI, IoT, and Robotics

Industrial automation is rapidly evolving, driven by key technologies such as artificial intelligence (AI), the Internet of Things (IoT), and robotics. AI enhances operational efficiency by enabling machines to learn from data, predict maintenance needs, and optimize processes in real-time. With machine learning algorithms, organizations can minimize downtime and streamline workflows, leading to significant productivity gains. AI-powered analytics can also enhance decision-making, allowing businesses to respond swiftly to changing market conditions.

The IoT connects devices and systems across manufacturing environments, facilitating seamless communication and data sharing. This interconnectedness enables real-time monitoring of equipment and processes, allowing for predictive maintenance and automation of tasks that were previously manual. By integrating IoT solutions, industries can achieve greater visibility into their operations, leading to more informed strategies for optimizing resource allocation and reducing waste.

Robotics plays an equally significant role in industrial automation, from the use of collaborative robots, known as cobots, that work alongside human operators to fully autonomous machines handling complex tasks. These advancements not only increase production speed but also enhance safety by taking over hazardous jobs in environments such as manufacturing floors or assembly lines. As these technologies converge, they create a more efficient production ecosystem, ultimately driving innovation and competitiveness in the industrial sector.

Top Industrial Automation Solutions to Improve Efficiency and Productivity

| Technology | Description | Benefits | Implementation Challenges |

|---|---|---|---|

| Artificial Intelligence (AI) | AI technologies that analyze data and make intelligent decisions. | Increased productivity, predictive maintenance, enhanced quality control. | Data privacy concerns, high implementation costs, and lack of skilled personnel. |

| Internet of Things (IoT) | Network of connected devices that collect and exchange data. | Real-time monitoring, improved asset utilization, enhanced operational efficiency. | Interoperability issues, security vulnerabilities, and data overload. |

| Robotics | Use of robotic systems to automate repetitive tasks. | Reduced labor costs, increased speed, higher precision. | High initial investment, maintenance requirements, and workforce displacement concerns. |

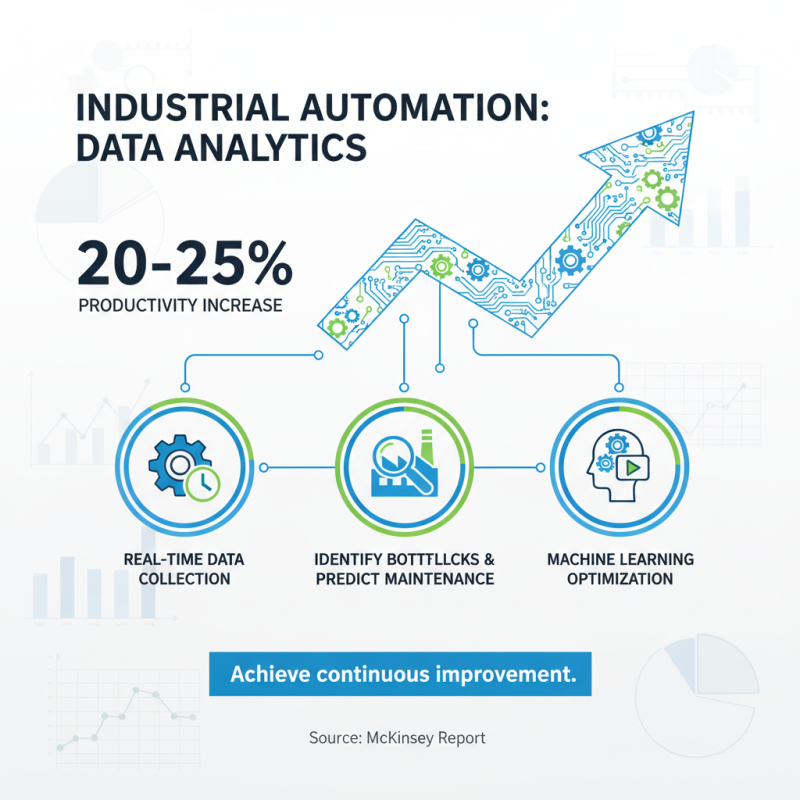

The Role of Data Analytics in Enhancing Productivity in Automation Systems

In the realm of industrial automation, data analytics plays a pivotal role in enhancing productivity and efficiency. According to a recent report by McKinsey, companies that incorporate advanced analytics into their automation systems can achieve productivity increases of up to 20-25%. This is achieved by collecting real-time data from machinery and production processes, enabling organizations to identify bottlenecks, predict maintenance needs, and optimize operations. The integration of machine learning algorithms allows for continuous improvement, as systems learn from historical data and adapt to changing circumstances.

To maximize the benefits of data analytics in automation, organizations should focus on developing a robust data strategy. One useful tip is to ensure that data is collected consistently and accurately across all systems—this foundation allows for reliable analysis. Furthermore, encouraging a culture of data-driven decision-making among employees can lead to innovative solutions and increased operational insights. As highlighted in a report by Gartner, companies that prioritize data literacy programs often see a 10% higher return on investment from their analytics initiatives.

Another important aspect is investing in visualization tools that transform complex data into understandable insights. With effective data visualization, key stakeholders can quickly grasp performance metrics and operational trends, facilitating faster and more informed decision-making. By leveraging these strategies, businesses can enhance their automation systems, leading to significant improvements in productivity and overall efficiency.

Case Studies: Successful Implementations of Automation in Various Industries

In recent years, various industries have turned to industrial automation to enhance their efficiency and productivity. One notable example is the automotive industry, where companies have successfully integrated robotics into their assembly lines. This implementation has not only streamlined production processes but has also significantly reduced the margin of error associated with manual labor. As a result, manufacturing times have decreased, allowing companies to respond more rapidly to market demands while maintaining high-quality standards.

Another compelling case can be found in the food processing sector, where automation technologies have been introduced to optimize packaging and sorting operations. By employing advanced sensors and automated machinery, businesses can achieve higher throughput and better quality control, minimizing spoilage and waste. These advancements not only lead to cost savings but also enhance overall product consistency, which is critical in maintaining customer satisfaction and adherence to safety regulations. Such successful implementations demonstrate the transformative potential of industrial automation across diverse sectors, resulting in measurable improvements in operational performance.

Conclusion

The article "Top Industrial Automation Solutions to Improve Efficiency and Productivity" explores how various industrial automation solutions can significantly enhance operational efficiency and productivity. It begins with an overview of industrial automation, detailing its fundamental principles and the profound impact it has on efficiency across sectors. The discussion highlights key technologies driving this transformation, such as Artificial Intelligence (AI), the Internet of Things (IoT), and robotics, all of which contribute to the automation revolution.

Moreover, the role of data analytics is emphasized, showcasing its importance in optimizing productivity within automated systems. Through case studies, the article illustrates successful implementations of these solutions across different industries, demonstrating tangible benefits. Finally, it addresses the evaluation of return on investment (ROI) in automation initiatives, providing insights into how organizations can measure the impact of these industrial automation solutions on their overall operational efficiency.