Why Choose Manufacturing Automation Software for Your Business Efficiency?

In today's competitive landscape, maximizing efficiency is critical for manufacturing businesses. A compelling strategy involves implementing manufacturing automation software. According to a report by McKinsey, automating production processes can enhance productivity by up to 30%. This shift not only streamlines operations but also reduces labor costs and minimizes errors.

Yet, the transition to automation presents challenges. Many companies have reported initial setbacks in integrating new software. A Deloitte study highlighted that 40% of manufacturers hesitate to adopt automation due to a lack of skilled personnel. This gap needs addressing, as effective training can significantly reduce the learning curve.

Investing in manufacturing automation software can lead to substantial long-term gains. It allows businesses to better respond to market demands and improve product quality. However, businesses must carefully evaluate their specific needs. Overlooking customization can result in wasted resources and diminished outcomes. Hence, reflecting on these aspects is essential before making a shift.

Benefits of Manufacturing Automation Software for Operational Efficiency

Manufacturing automation software significantly improves operational efficiency. According to a recent report from the International Federation of Robotics, productivity in automated environments can increase by up to 30%. This means businesses can produce more with fewer resources. For example, companies utilizing automation see a reduction in labor costs and an increase in output quality.

However, implementing this technology isn't without its challenges. Many businesses struggle with integrating new software into their existing systems. A study by Deloitte highlights that 58% of companies report initial setbacks when shifting to automated solutions. Training staff and adjusting workflows may require additional time and investment. It's crucial to navigate these challenges thoughtfully.

Automation also helps in data collection and analysis. This data-driven approach allows businesses to make informed decisions. For instance, real-time performance metrics can identify inefficiencies in production lines. Yet, relying heavily on software may lead to overdependence. Balancing human oversight and automated processes is vital to maintain operational resilience. Businesses must reflect on their unique needs when choosing automation solutions.

Key Features to Consider in Manufacturing Automation Solutions

Manufacturing automation software is key to improving business efficiency. When selecting the right solution, various features should be evaluated carefully. Flexibility is one of the most important factors. Choose software that adapts to your production requirements. This adaptability ensures smoother operations, reducing downtime.

Another vital feature is real-time data analytics. With accurate insights, businesses can identify issues quickly. This capability also enhances decision-making processes. Visibility into production metrics helps track performance and optimize workflow.

Tips: Regularly review your automation tools. Adaptability can sometimes be overlooked. Not every feature will be used daily, but it's essential to have the right ones in place. Also, consider user-friendly interfaces. Complex systems can hinder efficiency. Simple designs often yield better results. Investing time in training staff can further amplify benefits.

Remember, not every automation solution is perfect. Sometimes, initial implementation may not meet expectations. Companies must be willing to reflect on their progress. Continuous improvements are necessary for true efficiency.

Manufacturing Automation Software Impact on Business Efficiency

This chart illustrates the percentage of performance improvement experienced by businesses after implementing manufacturing automation software. Key dimensions include product quality, production speed, cost reduction, employee productivity, and order accuracy.

The Role of Data Analytics in Enhancing Production Processes

Data analytics is revolutionizing manufacturing processes. It enables businesses to collect data from various sources. This data can then be analyzed to identify trends and inefficiencies. For instance, real-time monitoring can pinpoint equipment failures before they escalate. This proactive approach minimizes downtime, boosting overall efficiency.

Moreover, data analytics provides insights into production schedules. Businesses can adjust workflows based on demand patterns. A company might find that certain products sell better during specific seasons. By anticipating these trends, manufacturers can optimize inventory levels. However, relying solely on data can be misleading. Data might not capture all nuances of production challenges, leading to oversight.

Integrating data analytics also comes with challenges. Many companies struggle to train staff on new systems. Resistance to change can impair data-driven decision-making. Additionally, data privacy is a growing concern. Businesses must navigate these complexities while striving for efficiency. Finding the right balance is essential for leveraging data analytics successfully.

Implementing Automation Software: Challenges and Best Practices

Implementing automation software can greatly enhance business efficiency. Yet, challenges often arise during the process. One common issue is employee resistance. Workers may fear job loss or changes to their routines. This fear can hinder productivity and morale. Engage your team early in the process. Discuss the benefits of automation, emphasizing how it can simplify their work.

Tips: Provide training sessions. Help employees understand new systems. Addressing concerns openly can ease transitions.

Integration difficulties are another challenge. Existing systems may not align well with new software. Conduct thorough compatibility assessments before implementation. A phased approach can also help. This allows for gradual adjustments and minimizes disruption.

Tips: Document processes carefully. Clear documentation aids in troubleshooting. Encourage feedback from all users throughout the integration phase.

Monitoring performance post-implementation is critical. Track key metrics to evaluate efficiency gains. Adapt and refine processes based on real-world feedback. Reflect on what works and what doesn’t. This iterative approach fosters continuous improvement. Make it a habit to reassess software efficacy regularly.

Why Choose Manufacturing Automation Software for Your Business Efficiency? - Implementing Automation Software: Challenges and Best Practices

| Aspect | Description | Challenges | Best Practices |

|---|---|---|---|

| Cost Reduction | Automation software helps lower production costs by reducing manual labor. | Initial investment and ongoing maintenance costs can be high. | Conduct a thorough ROI analysis before implementation. |

| Efficiency Improvement | Streamlines processes and speeds up production timelines. | Integration with existing systems may be difficult. | Ensure software is compatible with current systems and provides training. |

| Data Analysis | Facilitates better data collection and analysis for informed decision-making. | Data security concerns can arise. | Implement strong cybersecurity measures and regular audits. |

| Quality Control | Improves product quality through precise repetitive tasks. | Resistance to change from employees may occur. | Involve employees in training and change management processes. |

| Scalability | Allows businesses to easily scale operations up or down. | Scaling may require additional investments in resources. | Plan for future growth in your initial software selection. |

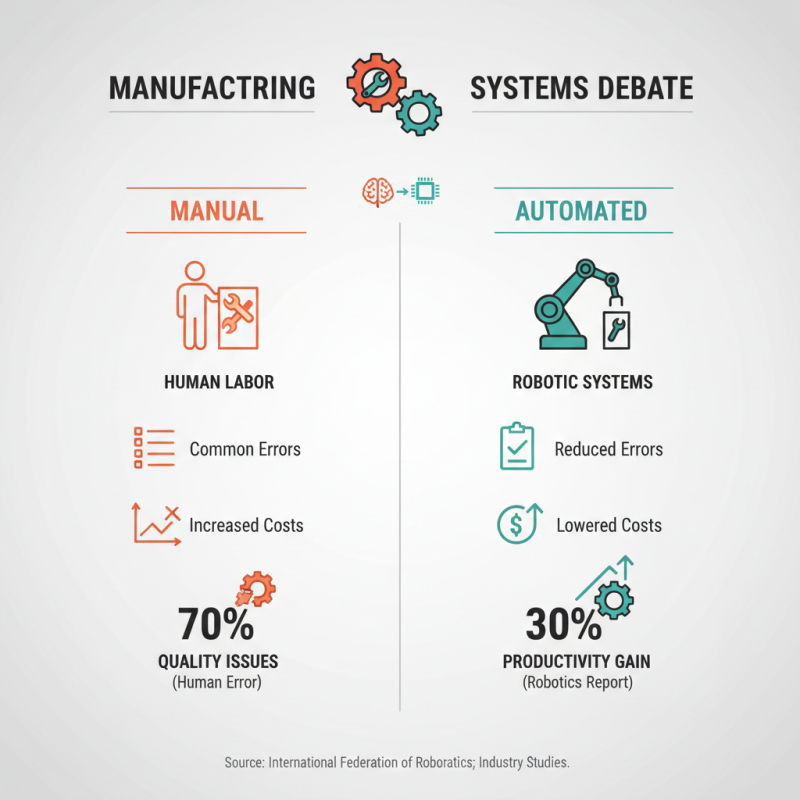

Comparative Analysis: Manual vs. Automated Manufacturing Systems

The debate between manual and automated manufacturing systems is crucial for today's businesses. According to a report by the International Federation of Robotics, automation can improve productivity by up to 30%. Manual systems often struggle with errors, leading to increased costs. A study revealed that around 70% of manufacturers faced quality issues due to human error.

On the other hand, automated systems provide consistency and efficiency. For instance, companies can achieve a reduction in cycle times by nearly 50% through automation. However, adopting this technology requires a significant upfront investment. Some businesses find it challenging to transition from traditional methods. They often deal with a learning curve that could hinder immediate productivity gains.

In examining manual versus automated systems, it's evident that automation offers superior efficiency. Yet, the shift isn't always smooth. Companies might grapple with the complexities of integration. Decisions should not solely focus on immediate cost savings. Long-term operational goals and workforce adaptation are equally vital in this transformation process.

Related Posts

-

Understanding Control Systems Automation Types and Their Applications

-

2025 Guide: How to Control Automation for Maximum Efficiency and Safety

-

10 Best Automation Services to Streamline Your Business Operations

-

10 Best Control Systems for Efficient Automation and Management?

-

How to Build and Optimize Automatic Systems for Maximum Efficiency

-

Top Industrial Automation Solutions to Improve Efficiency and Productivity