China's Smart Manufacturing: The Global Success Story Behind the Best Automobile Suspension Systems with Quality Assurance

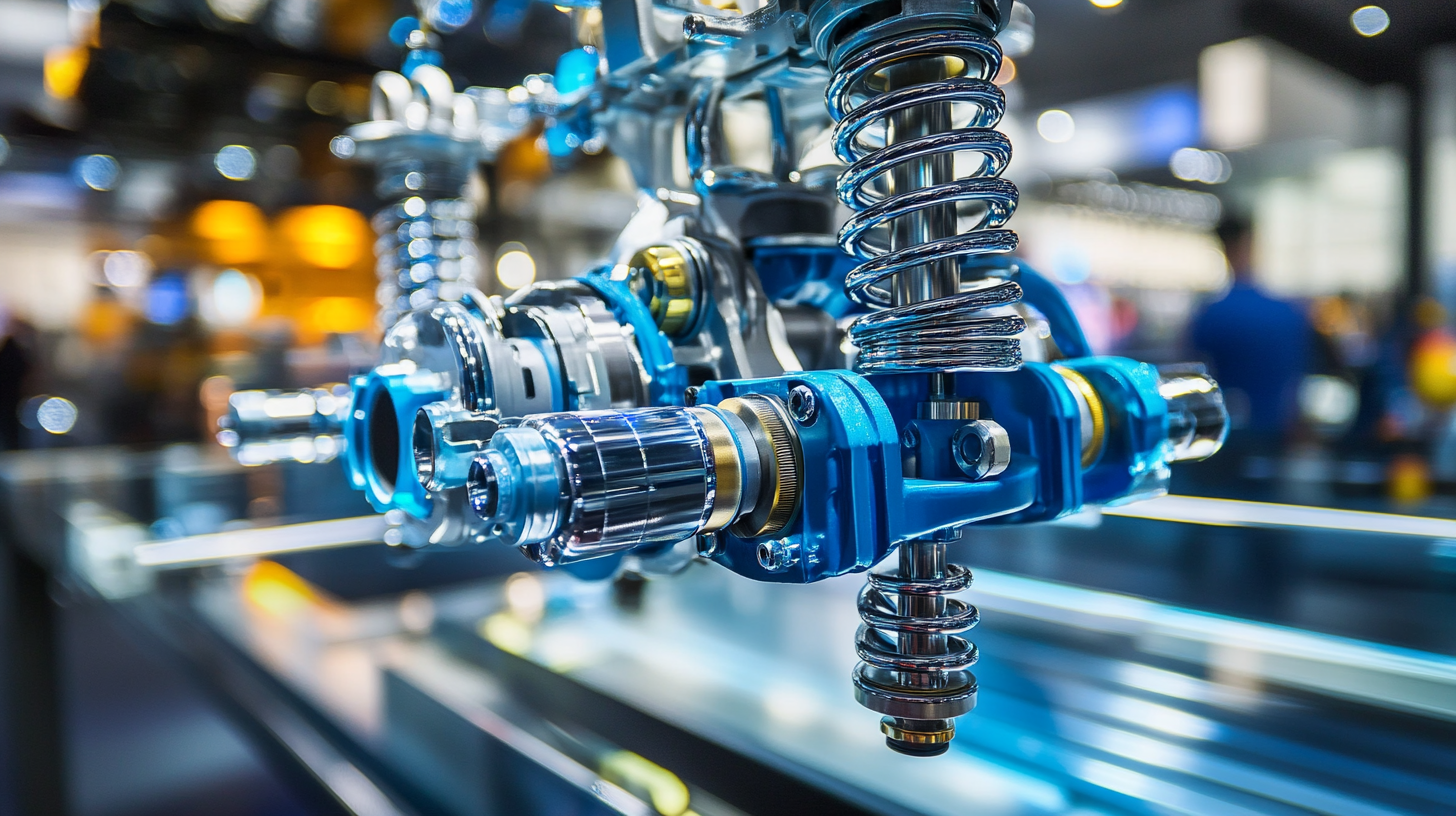

In the realm of automotive engineering, the Automobile Suspension System stands as a critical component that enhances vehicle safety, performance, and comfort. As the global automotive industry evolves, China has emerged as a formidable player in smart manufacturing, showcasing an impressive ability to produce high-quality suspension systems that rival the best in the world. This blog delves into the remarkable journey of China’s smart manufacturing sector, exploring the innovative technologies, rigorous quality assurance processes, and industry comparisons that set its automobile suspension systems apart. Through a closer look at the key players and the strategies they employ, we will unravel the success story behind China's automotive engineering prowess, highlighting how these advancements contribute significantly to the global automotive landscape. Join us as we examine the intricate balance of quality, efficiency, and technological advancement in the creation of superior automobile suspension systems.

In the realm of automotive engineering, the Automobile Suspension System stands as a critical component that enhances vehicle safety, performance, and comfort. As the global automotive industry evolves, China has emerged as a formidable player in smart manufacturing, showcasing an impressive ability to produce high-quality suspension systems that rival the best in the world. This blog delves into the remarkable journey of China’s smart manufacturing sector, exploring the innovative technologies, rigorous quality assurance processes, and industry comparisons that set its automobile suspension systems apart. Through a closer look at the key players and the strategies they employ, we will unravel the success story behind China's automotive engineering prowess, highlighting how these advancements contribute significantly to the global automotive landscape. Join us as we examine the intricate balance of quality, efficiency, and technological advancement in the creation of superior automobile suspension systems.

China's Rise as a Leader in Smart Manufacturing for Automobile Suspension Systems

China has emerged as a formidable leader in smart manufacturing, particularly in the production of automobile suspension systems. According to a recent report by the China Automotive Technology and Research Center, the country is now responsible for over 30% of global suspension system production, a figure that highlights its growing significance in the automotive supply chain. The adoption of advanced technologies, such as artificial intelligence and IoT, has allowed Chinese manufacturers to enhance quality control and optimize production efficiency, ultimately leading to superior suspension systems that meet international standards.

The implementation of smart manufacturing practices has streamlined production processes, resulting in a reported 20-30% reduction in lead times, as noted in a 2022 industry analysis by McKinsey. Furthermore, data from Statista indicate that the global automotive suspension market is expected to reach $42 billion by 2025, with Chinese companies poised to capture a substantial market share. This competitive edge is attributable to strategic investments in research and development, which have enhanced product innovation and reliability, reinforcing China's status as a key player in the automotive industry worldwide.

China's Smart Manufacturing: The Global Success Story Behind the Best Automobile Suspension Systems with Quality Assurance

| Dimension |

Value |

| Annual Production Capacity |

2,500,000 units |

| Average Defect Rate |

1.2% |

| Investment in R&D (Annual) |

$300 million |

| Number of Patents Filed |

500+ |

| Employee Training Hours (Annual) |

150,000 hours |

| Export Percentage |

40% |

| Sustainability Initiatives |

30% renewable energy utilization |

The Crucial Role of IoT and Big Data in Enhancing Quality Assurance

In the rapidly evolving landscape of smart manufacturing, the integration of IoT and big data has become pivotal in ensuring the quality of automobile suspension systems. The use of Internet of Things (IoT) technology enables manufacturers to connect various components of the production process, facilitating real-time monitoring and control. For instance, sensors embedded within the production line can continually collect data on materials, machinery performance, and environmental conditions. This constant stream of information allows for immediate identification of any discrepancies or potential faults, thereby minimizing defects and enhancing overall product quality.

Moreover, big data analytics plays a crucial role in transforming the vast amounts of data generated through IoT devices into actionable insights. By applying advanced analytical techniques, manufacturers can identify trends, predict future performance, and make informed decisions to improve processes. This data-driven approach not only reduces the likelihood of quality issues but also streamlines production, ultimately leading to significant cost savings and customer satisfaction. As smart manufacturing continues to evolve, the symbiotic relationship between IoT and big data will undeniably shape the future of quality assurance in the automotive industry.

Key Industry Metrics: Production Rates and Quality Control in China's Suspension Systems Market

China has emerged as a pivotal player in the global automotive suspension systems market, driven by its commitment to smart manufacturing and stringent quality control measures. With production rates steadily increasing, the country is set to dominate the market as it expands its footprint beyond domestic consumption. The focus on advanced technologies and automation not only enhances efficiency but also ensures that every suspension system meets the highest quality standards, crucial for maintaining safety and performance in vehicles.

China has emerged as a pivotal player in the global automotive suspension systems market, driven by its commitment to smart manufacturing and stringent quality control measures. With production rates steadily increasing, the country is set to dominate the market as it expands its footprint beyond domestic consumption. The focus on advanced technologies and automation not only enhances efficiency but also ensures that every suspension system meets the highest quality standards, crucial for maintaining safety and performance in vehicles.

As the demand for high-quality automotive components rises globally, China's ability to integrate innovative production techniques and rigorous quality assurance protocols positions it for significant growth. This is evidenced by the projected market growth for automotive suspension systems, which reflects strong consumer confidence in the quality and reliability of Chinese-manufactured products. Moreover, as international collaborations strengthen, Chinese manufacturers are well-equipped to leverage global market trends, thereby propelling their growth in a competitive landscape.

Challenges Faced by Chinese Manufacturers in Ensuring Global Standards

Chinese manufacturers have made remarkable strides in producing high-quality automobile suspension systems that compete on a global scale. However, the journey towards achieving international quality standards is fraught with challenges. One major difficulty lies in the rapid pace of technological advancement. Manufacturers must continuously invest in research and development to keep up with innovations in material science and engineering practices. Failure to adapt can lead to obsolescence, making it imperative to stay ahead in this competitive industry.

Quality assurance is another significant hurdle. Chinese manufacturers often face scrutiny regarding the consistency and reliability of their products. Establishing robust quality control processes is essential, yet many companies struggle with the integration of advanced inspection technologies and certification management systems. Moreover, navigating the complex landscape of global regulations adds another layer of difficulty, as adherence to different standards in various markets can be resource-intensive and complex. As the automotive industry increasingly demands high levels of compliance, only those manufacturers who prioritize quality and invest in necessary improvements will secure their place in the global market.

Global Quality Assurance in Automobile Suspension Systems

This chart illustrates the average quality assurance scores of automobile suspension systems produced in China compared to global standards.

Future Trends: Innovations Shaping the Next Generation of Suspension Systems in China

China’s automotive industry is at the forefront of technological advancement, particularly in the realm of suspension systems. Innovations such as adaptive suspension technologies and lightweight materials are transforming vehicle dynamics and enhancing safety. The integration of artificial intelligence allows for real-time adjustments based on road conditions and driver behavior, resulting in smoother rides and improved handling.

Additionally, the emphasis on sustainability is driving the evolution of suspension system manufacturing. Companies are exploring biodegradable and recyclable materials, aiming to reduce the automotive footprint. The advent of smart materials that can adjust their properties in response to various stimuli heralds a new era in suspension design. As these innovations continue to shape the industry, China is not only setting standards for quality assurance but also leading the charge in creating a more efficient and environmentally friendly automotive landscape.

In the realm of automotive engineering, the Automobile Suspension System stands as a critical component that enhances vehicle safety, performance, and comfort. As the global automotive industry evolves,

In the realm of automotive engineering, the Automobile Suspension System stands as a critical component that enhances vehicle safety, performance, and comfort. As the global automotive industry evolves,  China has emerged as a pivotal player in the global automotive suspension systems market, driven by its commitment to smart manufacturing and stringent quality control measures. With production rates steadily increasing, the country is set to dominate the market as it expands its footprint beyond domestic consumption. The focus on advanced technologies and automation not only enhances efficiency but also ensures that every suspension system meets the highest quality standards, crucial for maintaining safety and performance in vehicles.

China has emerged as a pivotal player in the global automotive suspension systems market, driven by its commitment to smart manufacturing and stringent quality control measures. With production rates steadily increasing, the country is set to dominate the market as it expands its footprint beyond domestic consumption. The focus on advanced technologies and automation not only enhances efficiency but also ensures that every suspension system meets the highest quality standards, crucial for maintaining safety and performance in vehicles.