How to Build and Optimize Automatic Systems for Maximum Efficiency

In today's rapidly evolving technological landscape, businesses are increasingly investing in automatic systems to streamline operations and enhance productivity. The integration of automation allows organizations to minimize human error, reduce operational costs, and maximize efficiency across various processes. As industries seek to stay competitive, understanding how to build and optimize these automatic systems becomes paramount. Effective implementation of automation not only facilitates smoother workflows but also empowers teams to focus on more strategic tasks, driving innovation and growth.

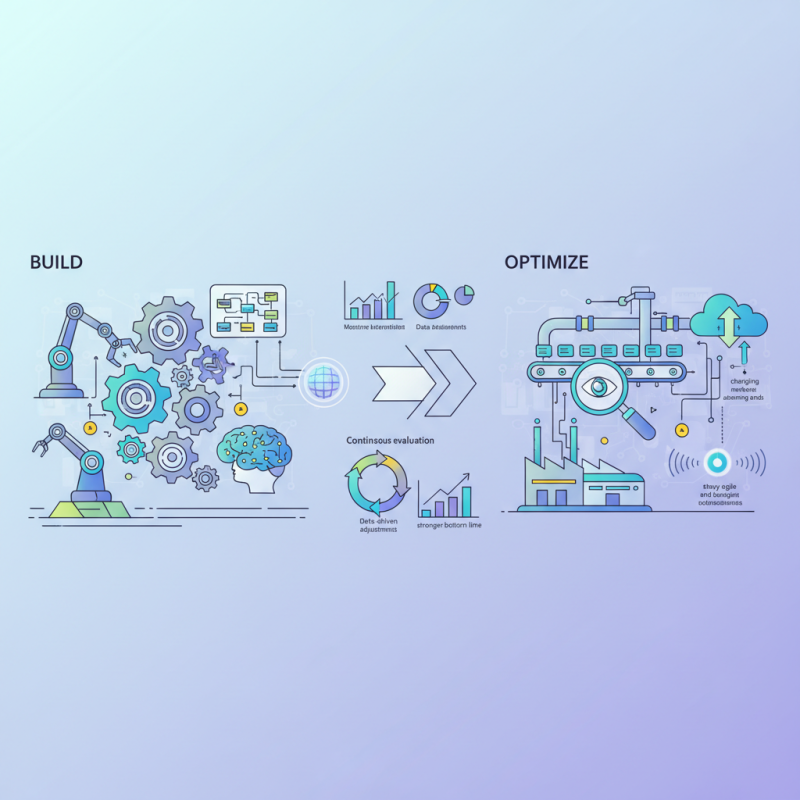

To construct an efficient automatic system, it is essential to assess existing processes and identify areas ripe for improvement. This involves a comprehensive analysis of workflow dynamics, resource allocation, and the potential for integrating advanced technologies such as machine learning and artificial intelligence. By strategically aligning these systems with organizational goals, companies can ensure that their automation initiatives are both effective and sustainable, ultimately leading to enhanced performance and a stronger bottom line.

Moreover, optimizing automatic systems requires continuous evaluation and adaptation. Businesses must remain agile, making data-driven adjustments to their systems in response to changing market demands and technological advancements. By fostering a culture of continuous improvement and embracing the potential of automatic systems, organizations can unlock significant efficiencies and secure a competitive edge in their respective industries.

Understanding the Basics of Automatic Systems and Their Importance

Automatic systems have become increasingly critical in today’s fast-paced business environment, known for their ability to enhance operational efficiency and minimize human error. A report by McKinsey & Company highlights that automation can unlock $16 trillion in global economic activity by 2030, emphasizing its paramount importance across various industries. These systems reduce the need for manual interventions, allowing businesses to streamline their processes and focus on core activities, thus boosting productivity.

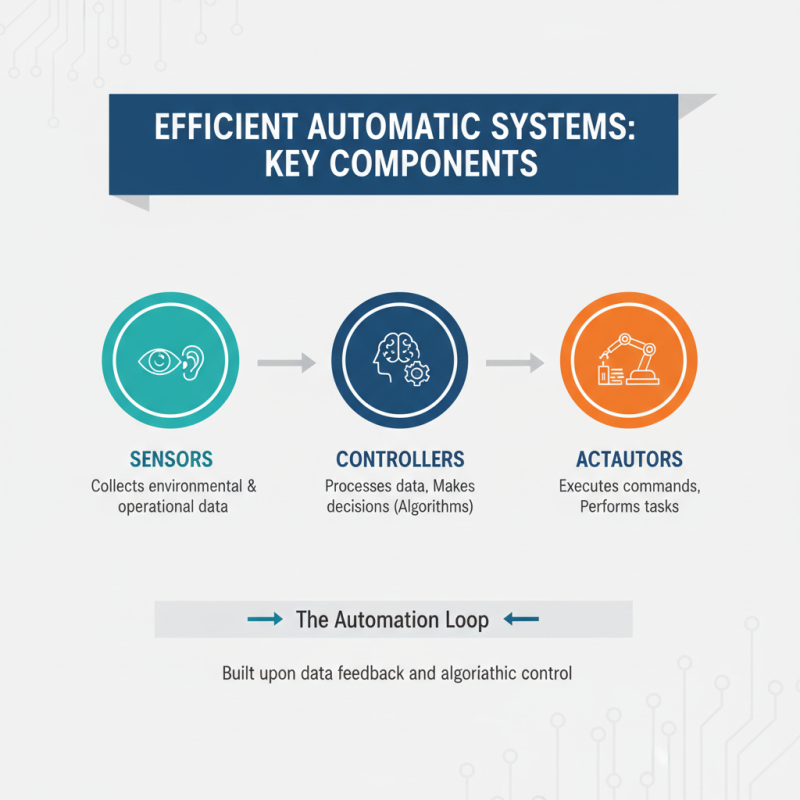

Understanding the basics of automatic systems involves recognizing their key components, such as sensors, controls, and actuators, which work together to perform specific tasks autonomously. According to a study by PwC, nearly 45% of work activities could be automated using existing technologies, showcasing the potential for significant labor cost savings. Furthermore, as businesses adopt automated solutions, they not only improve efficiency but also enhance accuracy and reliability in operations, leading to increased customer satisfaction and competitive advantage. As organizations strive for maximum efficiency, the integration of automatic systems stands out as a pivotal strategy for achieving sustainable growth in an increasingly digital world.

How to Build and Optimize Automatic Systems for Maximum Efficiency

| System Component | Function | Optimization Techniques | Efficiency Metric |

|---|---|---|---|

| Sensor Systems | Data Collection | Calibration, Regular Updates | Accuracy Rate (%) |

| Control Systems | Process Management | PID Tuning, Fuzzy Logic | Response Time (ms) |

| Data Processing Units | Data Analysis | Algorithm Optimization, Load Balancing | Throughput (records/sec) |

| User Interface | User Interaction | A/B Testing, User Feedback | User Satisfaction (%) |

| Feedback Mechanisms | System Updates | Regular Reviews, User Surveys | Adaptation Rate (%) |

Identifying Key Components for Building Efficient Automatic Systems

Building efficient automatic systems requires a keen understanding of their key components. To start, it is crucial to identify and integrate the essential elements such as sensors, controllers, and actuators. Sensors are the eyes and ears of your system, collecting data about the environment and the operational state of machinery. Controllers process this information and make decisions based on predetermined algorithms, while actuators execute these commands, enabling the system to perform tasks autonomously.

Tips: Always ensure that your sensors are calibrated correctly to maintain accuracy in data collection. Regularly updating the control algorithms is also vital to accommodate changes in operational requirements or advancements in technology.

Another important aspect is the optimization of communication between these components. Implementing robust communication protocols will enhance the system's responsiveness and reliability. Additionally, conducting thorough testing and iteration of the system can help pinpoint inefficiencies and areas for improvement. Investing time in this phase can lead to significant gains in performance and energy efficiency.

Tips: Utilize simulation software for testing before physical implementation. This can save time and resources by identifying potential issues in a controlled environment.

Strategies for Optimizing Performance in Automatic Systems

To optimize performance in automatic systems, it is essential to begin with a thorough analysis of the existing workflows. By identifying bottlenecks and inefficiencies, one can implement targeted interventions that enhance system functionality. This may involve upgrading hardware components to increase processing speeds or utilizing advanced algorithms that streamline decision-making processes.

Additionally, regular monitoring of system performance metrics should be established to pinpoint areas for ongoing improvement.

Another critical strategy involves incorporating adaptive learning mechanisms within automatic systems. These systems can benefit from machine learning techniques that allow them to gather data over time, enabling them to adjust operations based on real-time performance feedback. This adaptability not only minimizes downtime but also ensures that systems maintain optimal efficiency as they evolve. Collaboration between human operators and automated solutions is equally vital; establishing clear communication channels ensures that any issues are promptly addressed, further boosting overall system efficacy.

Implementing Feedback Loops for Continuous Improvement

Implementing feedback loops is crucial for the continuous improvement of automatic systems aimed at maximizing efficiency. These loops create a structured mechanism for gathering data on system performance, identifying areas of inefficiency, and facilitating iterative enhancements. By regularly analyzing feedback, organizations can pinpoint the root causes of bottlenecks and implement targeted solutions, leading to an agile system that evolves over time rather than remaining static. This iterative process not only enhances operational effectiveness but also fosters a culture of innovation and adaptability.

To effectively implement feedback loops, it is essential to establish clear metrics for performance measurement. These metrics provide a baseline for evaluating progress and outcomes, ensuring that teams can make informed decisions based on real-time data. Regularly scheduled reviews of these metrics allow stakeholders to assess the impact of changes and refine their strategies accordingly. Additionally, incorporating diverse perspectives and insights into the feedback process can lead to more robust solutions, as collaborative input often uncovers hidden inefficiencies that might be overlooked in a more siloed approach. This proactive stance towards feedback not only optimizes systems but also engages team members, making them integral to the process of continuous improvement.

Evaluating and Measuring System Efficiency Over Time

Evaluating and measuring system efficiency over time is crucial for any organization looking to sustain and improve their operational performance. According to a report by McKinsey & Company, companies that leverage data analytics can improve their operational efficiency by up to 30%. This highlights the importance of establishing key performance indicators (KPIs) that align with your automation goals. By continuously monitoring these metrics, businesses can identify bottlenecks and areas that require enhancement, thus allowing for a data-driven approach to optimization.

In addition, a study published by the International Journal of Production Research emphasizes the necessity of regular assessments to adapt to changing market conditions and technological advancements. Organizations that implemented periodic efficiency evaluations were able to achieve a 25% increase in their throughput. To effectively measure system performance, it is essential to employ both quantitative and qualitative metrics. Metrics such as cycle time, downtime, and overall equipment effectiveness (OEE) provide a comprehensive view of system health. These evaluations not only assist in tracking progress but also foster a culture of continuous improvement, essential in today’s competitive landscape.

Related Posts

-

2025 How to Choose the Best Manufacturing Automation Software for Your Business

-

How to Choose the Right Industrial Automation Software for Your Business

-

2025 Top 10 Automation Equipment Trends Driving Industry Growth and Efficiency

-

Understanding Control Systems Automation for Enhanced Efficiency and Performance

-

Top Automation Control Trends to Watch in 2025 for Enhanced Efficiency

-

Top Industrial Automation Solutions to Improve Efficiency and Productivity