2026 Best Automatic Control Systems for Efficient Performance and Reliability?

In the rapidly evolving field of automatic control systems, efficiency and reliability remain paramount. Dr. Emily Tran, an expert in automation engineering, emphasizes, "The future of automatic control systems relies on our ability to innovate and adapt." Her insight highlights the critical need for systems that not only perform well but also maintain stability in various industrial applications.

As industries strive for higher productivity, the demand for advanced automatic control systems grows. These systems are integral to sectors such as manufacturing, aerospace, and energy. They streamline processes and minimize human error. However, achieving optimal performance is not without its challenges. Companies must invest in research and development to address potential pitfalls.

Moreover, the integration of smart technologies poses both opportunities and hurdles. While automation enhances efficiency, it can also lead to system vulnerabilities. Addressing these concerns is essential for a reliable operational framework. The journey towards the best automatic control systems involves continuous learning and adaptation. Embracing feedback and evolving with technology are key to future advancements.

Overview of Automatic Control Systems and Their Importance

Automatic control systems play a pivotal role in various industries. They improve efficiency, ensure reliability, and enhance safety. According to the International Society of Automation (ISA), automated systems can increase productivity by up to 30%. This statistic highlights their importance in modern operations.

Operators benefit from these systems too. Data from the Control System Institute indicates that over 70% of companies report fewer errors and less downtime when using automation. This regression in failures often leads to substantial cost savings and improved customer satisfaction. However, reliance solely on automation without proper training can lead to lapses in human oversight.

Tips: Always invest in training for your team. Knowledge about the system fosters better decision-making. Regularly review performance metrics to identify areas for improvement. Automation is not infallible. Continuous evaluation is necessary. Embrace new technologies, but remain aware of their limitations. This balance will drive more efficient operations.

Key Features of High-Performance Automatic Control Systems

Automatic control systems are essential for enhancing efficiency and reliability in various industries. A high-performance system often features advanced algorithms that adapt to changing conditions. These algorithms help maintain optimal performance, minimizing energy consumption. Real-time data processing is crucial. It ensures that the system can respond to fluctuations instantly.

Another key feature is user-friendly interfaces. These interfaces allow operators to monitor and adjust system parameters easily. Accessibility is vital. A complex interface can lead to user errors, undermining reliability. Additionally, integration with other technologies can enhance system functionality. This synergy boosts overall performance.

However, challenges remain. Some systems struggle with data overload, leading to performance dips. Regular maintenance is vital, yet often overlooked. This oversight can result in inefficiencies. Feedback loops also need attention. If not calibrated correctly, they may introduce delays and inaccuracies. Continuous improvement is necessary for any automatic control system aiming for peak performance.

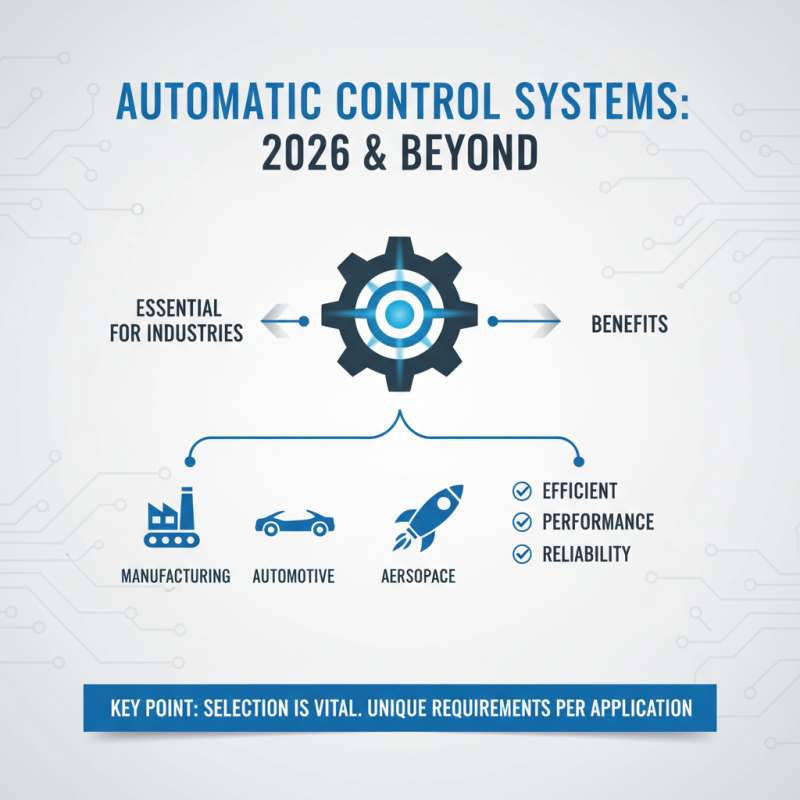

Top 2026 Automatic Control Systems for Various Applications

In 2026, automatic control systems are essential for many industries. These systems ensure efficient performance and reliability. They play a crucial role in sectors such as manufacturing, automotive, and aerospace. Each application has unique requirements. Therefore, selecting the right system is vital.

Tips: Consider the specific needs of your application. Analyze the environment where the system will operate. Reliability is key. A wrong choice can lead to failures. This can cause costly downtime.

Different control systems vary in complexity. Some may require significant expertise. Others are user-friendly, suitable for beginners. Do not overlook training needs for operators. Understanding the system’s functionality is crucial.

In some cases, integrating new technology can be challenging. Resistance from staff is common. It’s important to address concerns. Open discussions can facilitate smoother transitions. Continuous improvement should be a goal. Regular feedback can help refine processes.

Comparative Analysis of Reliability in Leading Control Systems

In the world of automatic control systems, reliability is paramount. A control system must respond accurately and consistently under various conditions. This ensures efficiency and safety in operations, from manufacturing to aerospace applications.

A comparative analysis reveals key factors affecting reliability. These include system architecture, redundancy, and response time. Systems with better redundancy tend to perform consistently, even when faced with unexpected failures. They incorporate backup mechanisms. This can reduce downtime significantly.

Tips: Always evaluate the system's response time under load. A system that responds swiftly can prevent costly operations from stalling. Additionally, test the backup components regularly to ensure they function when needed.

However, it's important to remember that not all systems are perfect. Some may exhibit issues under extreme conditions. A poorly designed control system might compromise safety. Regular reviews and updates are necessary to address potential shortcomings. Investing in training for personnel using these systems can also enhance reliability.

Future Trends in Automatic Control System Technologies

The landscape of automatic control systems is evolving rapidly. Emerging technologies promise to enhance efficiency and reliability significantly. Machine learning is driving substantial changes in control systems. It allows machines to learn from data and improve their performance over time. This trend is reshaping industries, from manufacturing to automotive.

Sensor technologies are becoming more advanced. They offer real-time data collection and analysis. With better sensors, systems can respond quickly to changes in the environment. However, reliance on sensors raises questions about data integrity and security. Can we trust these systems completely? The balance between efficiency and potential vulnerabilities needs careful consideration.

Future control systems will also emphasize sustainability. Energy-efficient technologies are crucial for reducing waste. However, developing these systems can be challenging. Engineers face the task of ensuring reliability while minimizing environmental impact. New materials and design strategies may help, but integrating them into existing frameworks poses its own difficulties. Finding this balance requires innovation and a willingness to experiment with novel approaches.

2026 Best Automatic Control Systems for Efficient Performance and Reliability

| System Type | Efficiency Rating | Reliability Index | Adaptability Score | User Satisfaction |

|---|---|---|---|---|

| PID Control System | 85% | 90% | 80% | 4.5/5 |

| Model Predictive Control | 90% | 95% | 85% | 4.7/5 |

| Fuzzy Logic Control | 80% | 88% | 90% | 4.2/5 |

| Sliding Mode Control | 88% | 92% | 87% | 4.4/5 |

| Neural Network Control | 92% | 94% | 89% | 4.6/5 |

Related Posts

-

Understanding Control Systems Automation Types and Their Applications

-

Top Automation Control Trends to Watch in 2025 for Enhanced Efficiency

-

Top 10 Benefits of Using Industrial Robots in Modern Manufacturing

-

Top 10 Control Systems Automation Trends You Can't Afford to Miss

-

2025 Guide: How to Control Automation for Maximum Efficiency and Safety

-

Exploring 2026 Top Process Control Systems Trends and Innovations?