Top 10 Benefits of Using Industrial Robots in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the integration of industrial robots has emerged as a transformative factor that redefines efficiency and productivity. According to Dr. Emily Carter, a renowned expert in robotics and automation, "Industrial robots are not just tools; they are catalysts for innovation that pave the way for a more agile and capable manufacturing ecosystem." These machines are increasingly being adopted across various industries, enhancing operational performance and maintaining competitiveness in a global market.

The benefits of employing industrial robots extend beyond mere automation; they include increased precision in production processes, reduced labor costs, and enhanced workplace safety. As manufacturers strive to meet consumer demands for higher quality products with shorter lead times, industrial robots provide the necessary consistency and reliability. This technology not only streamlines complex tasks but also allows human workers to engage in more strategic and creative roles within the production cycle.

With the growing reliance on industrial robots, companies are realizing the potential for significant return on investment. This outlines a promising future where manufacturers can harness the capabilities of robotic systems to innovate continually and adapt to changing market needs. As we explore the top 10 benefits of using industrial robots in modern manufacturing, it becomes evident that this technology is no longer a luxury but a necessity for survival and growth in today’s competitive landscape.

Advantages of Increased Efficiency and Productivity in Manufacturing

Industrial robots have revolutionized modern manufacturing by significantly enhancing efficiency and productivity. According to a report from the International Federation of Robotics, the installation of industrial robots has grown steadily, with an estimated increase of 12% in operational efficiency across various sectors in the last few years. This boost in efficiency is attributed to robots' ability to work continuously without fatigue, perform tasks with high precision, and reduce production times. Manufacturers leveraging robotics can thus streamline their operations, leading to lower operational costs and higher output rates.

One of the key advantages of using industrial robots is their capacity for consistent quality control. A study by McKinsey & Company highlights that automated processes reduce human error, resulting in a 30% decline in production defects. By implementing robotic solutions, companies can guarantee uniformity in their products, improving customer satisfaction and trust in their brand. Furthermore, robots can perform complex tasks in hazardous environments, allowing human workers to focus on more strategic roles and innovation.

Another important consideration is workforce participation in this transition. Training existing employees to work alongside robots enhances collaboration between human intelligence and machine efficiency. Invest in upskilling your staff to maximize the benefits of automation while fostering a culture that embraces technological advancements.

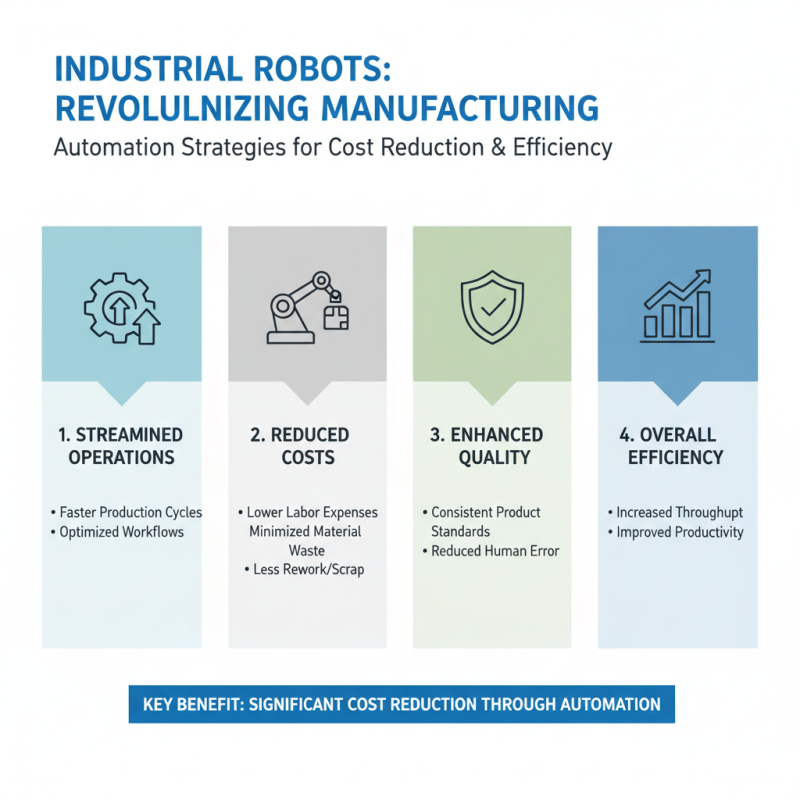

Reduction of Production Costs Through Automation Strategies

The implementation of industrial robots in modern manufacturing has revolutionized production processes, bringing about significant reductions in production costs through automation strategies. By leveraging advanced robotics, manufacturers can streamline operations, minimize waste, and enhance overall efficiency. Automation reduces the reliance on manual labor, which not only cuts labor costs but also decreases the likelihood of human error. This ensures a more consistent quality of products and reduces expenses related to rework and scrap.

Moreover, industrial robots can operate continuously, allowing for increased throughput without the limitations of human workforce schedules. This 24/7 productivity, combined with precise and fast robotic movements, means that production lines can run at their optimal capacity. The ability to swiftly adjust production schedules in response to market demands further enhances cost efficiency. Additionally, robots can perform complex tasks that might require multiple human operators, further consolidating labor costs and maximizing resource utilization. In this way, automation through robotics not only leads to immediate cost savings but also positions companies for long-term financial sustainability.

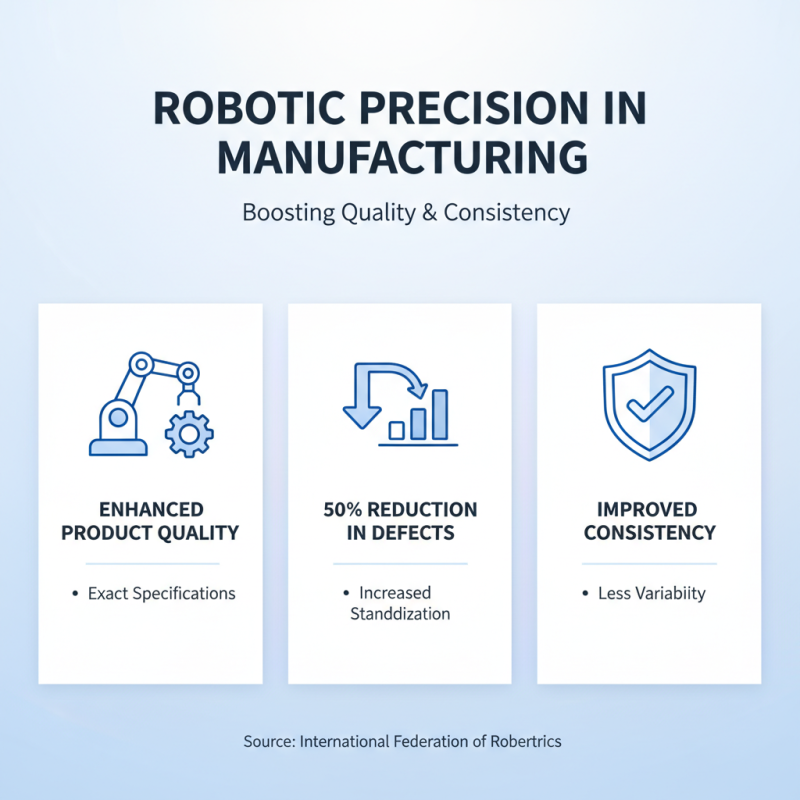

Improvement of Product Quality and Consistency with Robotic Precision

In today's competitive manufacturing landscape, the deployment of industrial robots has proven significant in improving product quality and consistency. Robotic precision enhances the manufacturing process by ensuring that each product is produced with exact specifications. According to a report by the International Federation of Robotics, manufacturers that integrate robotic systems witness a reduction in defects by up to 50%, demonstrating a substantial decrease in variability and an increase in standardization across production lines.

Moreover, robotic automation allows for continuous operation without the fatigue and variability inherent in human labor. A recent study from the McKinsey Global Institute indicates that businesses employing advanced robotic technologies can improve their throughput by as much as 30%. This increase in efficiency not only aligns with higher quality standards but also ensures that products meet stringent compliance regulations, which is crucial in sectors such as automotive and electronics. As manufacturers strive to meet growing consumer demands for quality and reliability, the integration of robotics provides a reliable solution to maintain and enhance product integrity over time.

Enhancement of Workplace Safety by Minimizing Human Error

The integration of industrial robots into modern manufacturing has significantly enhanced workplace safety by minimizing human error. In environments where precision and efficiency are crucial, robots handle repetitive tasks that are often the source of accidents. By taking on high-risk activities, such as heavy lifting or working with hazardous materials, robots reduce the likelihood of injuries that can occur due to fatigue or inattention among human workers. This shift not only protects employees but also fosters a more reliable production environment.

Furthermore, the use of robots allows for the implementation of advanced safety protocols. With robots equipped with sensors and safety features, the risk of collisions or accidents in the workplace is drastically lowered. This means that safety measures can be embedded into the workflow, creating a seamless interface between human workers and machines. As robots perform the more dangerous aspects of manufacturing, employees can focus on oversight and quality control, ultimately leading to a more secure and sustainable work environment.

Flexibility and Adaptability of Robots in Various Manufacturing Processes

In today's fast-paced manufacturing environment, the flexibility and adaptability of industrial robots play a crucial role in streamlining processes across various sectors. These advanced machines are designed to perform a wide range of tasks, from assembly and welding to packaging and quality inspection. Their ability to quickly switch between different tasks minimizes downtime and enhances productivity, allowing manufacturers to respond swiftly to market changes and customer demands.

One notable advantage of utilizing robots is their capability to be reprogrammed for new applications with relative ease. This not only reduces the need for extensive training but also cuts down on the time required to implement new production lines. As industries evolve, businesses can leverage robots to keep up with trends and continuously improve their operations.

Tips: When integrating industrial robots into your manufacturing processes, consider starting with a detailed assessment of your current workflows. Identify repetitive tasks that can be automated to free up human workers for more complex functions. Additionally, invest time in training your team on how to work alongside robots to maximize efficiency and leverage the full potential of this technology. Engaging your workforce in the transition can lead to smoother operations and enhanced morale.

Related Posts

-

Understanding Control Systems Automation Types and Their Applications

-

Top Automation Control Trends to Watch in 2025 for Enhanced Efficiency

-

How to Choose the Best Process Automation System for Your Business in 2025

-

Understanding Control Systems Automation for Enhanced Efficiency and Performance

-

2025 How to Choose the Best Manufacturing Automation Software for Your Business

-

10 Best Automation Services to Streamline Your Business Operations