Top Automation Control Trends to Watch in 2025 for Enhanced Efficiency

As we transition into 2025, the landscape of automation control is poised for transformative changes that promise to enhance operational efficiency across various industries. The rapid advancement of technology has sparked a wave of innovations that not only streamline processes but also optimize resource management. In this context, understanding the top automation control trends is crucial for businesses aiming to maintain a competitive edge in an increasingly automated world.

The integration of artificial intelligence, machine learning, and IoT technologies into automation control systems is becoming more prevalent, driving more intelligent and responsive frameworks. As these technologies evolve, organizations will be able to predict maintenance needs, reduce downtime, and enhance overall productivity. Moreover, the growing emphasis on sustainability and energy efficiency is steering the development of automation solutions that not only boost performance but also reduce environmental impact.

In this article, we will explore the key trends in automation control that are expected to reshape industries by 2025. By gaining insights into these developments, businesses can better prepare for the future, ensuring they harness the full potential of automation control to drive efficiency and innovation in their operations.

Automation Control Innovations Shaping the Future of Efficiency

The future of automation control is set to be revolutionized by a wave of innovative technologies designed to enhance efficiency across various industries. With advancements in artificial intelligence and machine learning, automation systems are becoming increasingly capable of analyzing vast amounts of data in real time. This enables organizations to make data-driven decisions that streamline operations and reduce costs. Predictive maintenance, powered by IoT sensors, is another key innovation, allowing businesses to anticipate equipment failures before they occur, thereby minimizing downtime and optimizing productivity.

Tips for implementing automation control innovations include starting small with pilot projects to test new technologies. This approach allows organizations to assess the impact of automation without overwhelming resources. Additionally, investing in employee training is crucial to ensure that teams are equipped to utilize new tools effectively. As companies adapt to these trends, fostering a culture that embraces change will empower employees to leverage automation to improve their workflows, driving overall efficiency.

Furthermore, the integration of cloud-based solutions in automation offers scalability and flexibility, enabling businesses to adjust their operations according to market demands swiftly. Companies should consider exploring cloud platforms that facilitate seamless data exchange and collaboration across departments. This interconnectedness not only enhances efficiency but also fosters innovation, making it essential for organizations to prioritize automation control as a key driver of future success.

Top Automation Control Trends to Watch in 2025 for Enhanced Efficiency

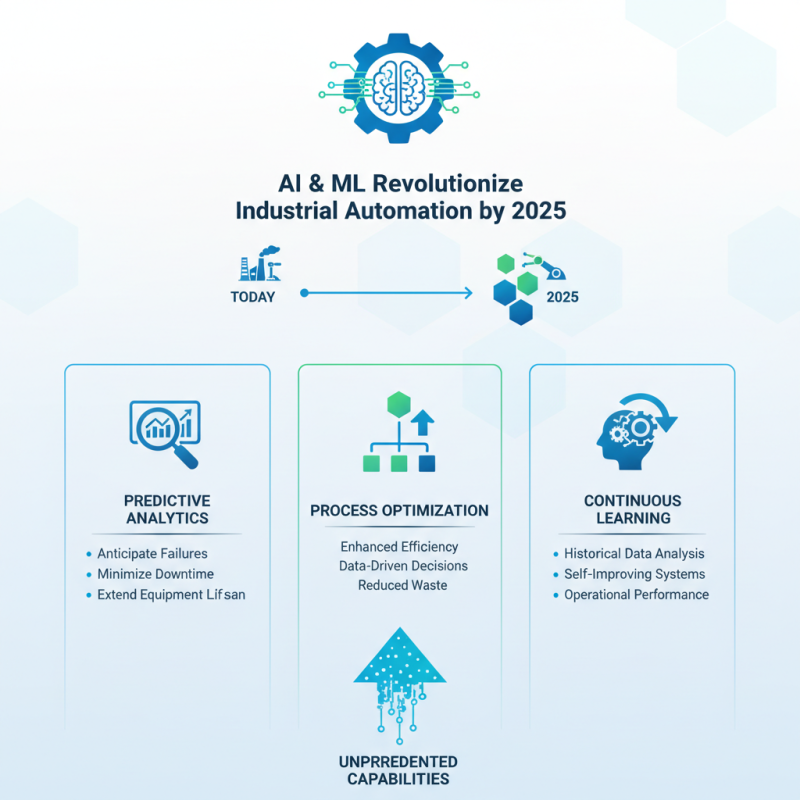

Integration of AI and Machine Learning in Automation Systems

The integration of AI and machine learning into automation systems is poised to revolutionize how industries operate by 2025. As businesses strive for enhanced efficiency, these technologies offer unprecedented capabilities in data analysis and process optimization. With AI algorithms capable of predictive analytics, organizations can anticipate failures and schedule preventative maintenance, thereby minimizing downtime and extending equipment lifespan. Machine learning enhances this further by enabling systems to learn from historical data, leading to continuous improvements in operational performance.

Tips for implementing AI and machine learning in your automation systems include starting with a clear identification of areas that would benefit from automation. Focus on processes with repetitive tasks or significant data generation, as these are ideal candidates for smart automation. Collaboration with data scientists and IT professionals can also be advantageous in designing effective machine learning models tailored to your specific needs.

As automation systems evolve, incorporating AI-driven insights will empower businesses to make real-time decisions based on data-driven evidence. Establishing a robust data management framework is essential to ensure that the information feeding into these systems is accurate and reliable. This proactive approach will cultivate an environment where efficiency is not just an objective but a continual outcome of intelligent automation.

The Rise of Predictive Maintenance in Automation Control

Predictive maintenance is emerging as a pivotal trend in automation control, driven by advancements in data analytics and machine learning technologies. This approach leverages real-time data collected from equipment and systems to foresee potential failures before they occur. By analyzing patterns and trends in operational data, companies can schedule maintenance tasks more effectively, minimizing downtime and reducing repair costs. This shift from reactive to predictive strategies not only enhances operational efficiency but also prolongs the lifespan of machinery and infrastructure.

Furthermore, the integration of Internet of Things (IoT) devices has significantly improved the efficacy of predictive maintenance. These smart sensors continuously monitor the health of equipment, providing a wealth of information regarding performance metrics. By utilizing this data, organizations can optimize maintenance schedules based on actual usage and condition, rather than relying on arbitrary timelines. As the technology evolves, the ability to predict failures with greater accuracy will become increasingly imperative for companies seeking to maintain a competitive edge and ensure seamless operations in their automated environments.

Top Automation Control Trends to Watch in 2025 for Enhanced Efficiency - The Rise of Predictive Maintenance in Automation Control

| Trend | Description | Expected Impact (%) | Implementation Timeline |

|---|---|---|---|

| Predictive Maintenance | Utilizing data analytics to predict equipment failures before they occur. | 25% | 2023 - 2025 |

| IoT Integration | Enhanced connectivity of machines for better data collection and analysis. | 30% | 2024 - 2025 |

| AI in Automation | Incorporating AI for process optimization and decision-making support. | 40% | 2024 - 2025 |

| Cybersecurity Enhancements | Improving security measures to protect automated systems from cyber threats. | 20% | 2023 - 2025 |

| Cloud-Based Solutions | Utilizing cloud technology for scalable and flexible automation control. | 35% | 2024 |

Impact of IoT on Automation Control Strategies

The impact of the Internet of Things (IoT) on automation control strategies is profound and transformative, particularly as industries move towards enhanced efficiency in 2025. IoT technology enables interconnected devices to communicate seamlessly, allowing for real-time data collection and analysis. This connectivity becomes the backbone of modern automation systems, enabling them to make informed decisions and respond to varying conditions instantaneously. As a result, organizations can optimize their operations, reduce downtime, and enhance productivity through advanced data insights.

Furthermore, the integration of IoT with automation control extends beyond operational improvements; it also fosters innovation in predictive maintenance and resource management. By employing IoT sensors and devices, companies can monitor equipment health and performance patterns, predicting failures before they occur. This proactive approach not only minimizes maintenance costs but also extends the lifespan of machinery. Additionally, IoT enables smarter resource allocation by analyzing consumption patterns, leading to more sustainable practices in manufacturing and service industries. As these trends accelerate, the collaboration between IoT and automation control will become essential for achieving greater efficiency and agility in the ever-evolving market landscape.

Sustainable Automation Solutions for Eco-Friendly Operations

As industries strive for greater efficiency, the integration of sustainable automation solutions is becoming increasingly vital. In 2025, companies will implement eco-friendly operations that rely on advanced automation technologies designed to reduce waste and lower energy consumption. Automation systems are evolving to include renewable energy sources, smart sensors, and data analytics that optimize processes while minimizing their environmental impact. By harnessing these technologies, businesses can achieve their operational goals without compromising sustainability.

Moreover, eco-friendly automation can lead to significant cost savings and enhanced productivity. Intelligent systems enable real-time monitoring and predictive maintenance, reducing downtime and resource waste. With the ability to analyze data effectively, companies can make informed decisions that promote sustainability, from sourcing materials to optimizing supply chains. This holistic approach to automation not only aligns with global sustainability goals but also resonates with consumers who increasingly favor environmentally responsible practices. Embracing these trends will empower businesses to innovate while contributing positively to the planet.