2025 Guide: How to Control Automation for Maximum Efficiency and Safety

As industries worldwide continue to embrace the transformative power of technology, the significance of effective control automation has never been more pronounced. According to a report from McKinsey & Company, automation could increase global productivity by up to 1.4% annually, which emphasizes the critical need for businesses to implement and refine their automation strategies. However, this rapid transition comes with its own set of challenges. A 2022 survey from Deloitte revealed that 63% of executives identified the lack of comprehensive control frameworks as a significant hurdle in their automation journeys.

To maximize efficiency while ensuring safety, organizations must prioritize the development of robust control automation systems. These systems not only streamline operations but also mitigate potential risks associated with automation. The World Economic Forum estimates that proper integration of control automation could lead to enhanced operational resilience, thereby reducing downtime by up to 25%. As we approach 2025, companies that leverage strategies for effective control automation will not only boost their competitive edge but also foster a safer working environment for their employees. This guide aims to provide insights and practical strategies for mastering control automation, ensuring that businesses can navigate the complexities of this technological evolution successfully.

Understanding Automation: Definitions and Key Concepts

Automation refers to the technology that allows processes or systems to operate with minimal human intervention.

It encompasses various tools and techniques, including robotics,

artificial intelligence, and control systems, designed to improve efficiency

and consistency in performing tasks.

Understanding automation is crucial, as it transforms traditional workflows by optimizing performance,

reducing errors, and enhancing safety measures.

Key concepts within the realm of automation include

feedback control, where systems adjust operations based on real-time data,

and interoperability, which allows different systems to work together seamlessly.

Additionally, the levels of automation can range from basic task automation to fully autonomous systems.

Comprehending these definitions enables organizations to identify where automation can be implemented effectively,

ensuring that they harness its full potential while maintaining safety standards in their operations.

This knowledge lays the foundation for strategic planning in automation adoption, directly impacting

operational efficiency.

The Importance of Efficiency and Safety in Automation

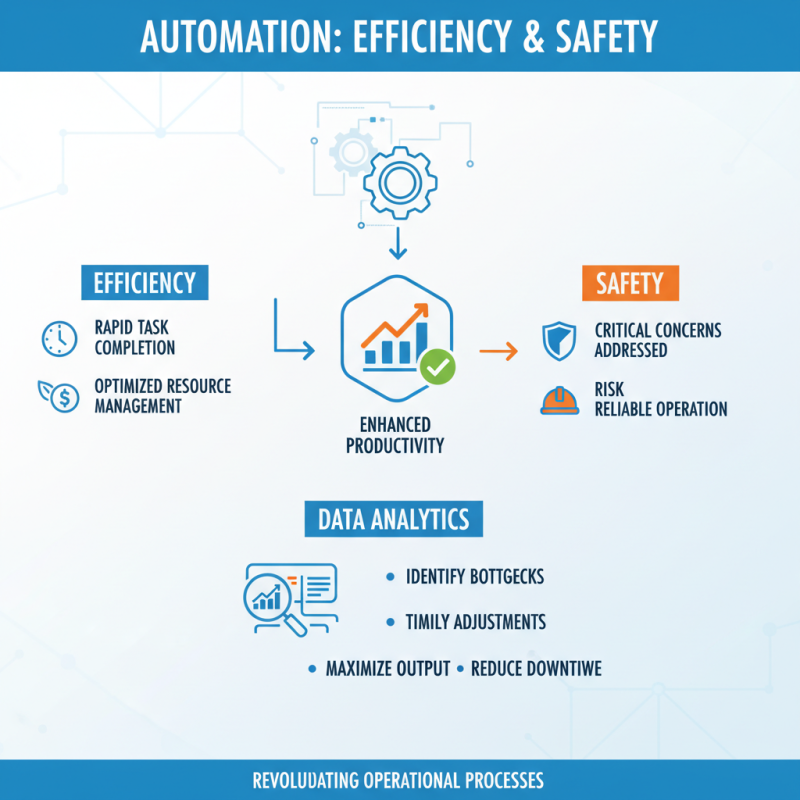

The integration of automation in various industries has revolutionized operational processes, yet it simultaneously raises critical concerns regarding efficiency and safety. Prioritizing efficiency ensures that automation systems are not only designed to complete tasks rapidly but also to optimize resource management. Streamlining workflows through automation eliminates redundancies, thus enhancing productivity levels. For instance, leveraging data analytics can identify bottlenecks in production lines, allowing for timely adjustments that maximize output and reduce downtime.

On the safety front, the implementation of automation must be approached with caution to mitigate risks associated with human-machine interaction. Proper safety protocols and fail-safes are essential to protect workers and machinery. This includes regular safety assessments, employee training sessions, and the incorporation of advanced sensors that monitor operational conditions in real-time. By fostering a culture of safety and ensuring that automated systems are equipped with the necessary safety features, organizations can create a working environment that promotes both high efficiency and robust safety standards, ultimately leading to sustainable success.

Strategies to Control Automation Systems for Optimal Performance

Effective management of automation systems is crucial for achieving optimal performance in any operational environment. One key strategy is the implementation of continuous monitoring and feedback mechanisms. By utilizing real-time data analytics, organizations can track the efficiency of automation processes, identify bottlenecks, and make swift adjustments to improve productivity. Regular assessments and adaptive strategies allow businesses to remain agile, ensuring that automated systems effectively align with changing operational needs and demands.

Another essential tactic is the integration of human oversight in automated processes. While automation enhances efficiency, it is vital to maintain human judgment for nuanced decision-making and troubleshooting. Training personnel to work alongside automation technologies ensures that they can intervene effectively whenever necessary. This not only enhances safety by preventing potential failures but also preserves the operational integrity of the system. By fostering a collaborative environment between human operators and automation systems, organizations can achieve a harmonious balance that promotes both efficiency and safety.

2025 Guide: How to Control Automation for Maximum Efficiency and Safety

| Automation Strategy | Description | Expected Benefits | Safety Measures | Implementation Time Frame |

|---|---|---|---|---|

| Predictive Maintenance | Utilizes data analytics to predict equipment failures before they occur. | Reduced downtime, increased operational lifespan of equipment. | Regular safety audits, fail-safes in software. | 3-6 months |

| Robotic Process Automation (RPA) | Automates routine tasks using software bots, enhancing efficiency. | Increased productivity, improved accuracy, cost savings. | Bot monitoring, access control mechanisms. | 1-3 months |

| Integrated Automation Systems | Combines multiple automation technologies into a single platform. | Improved coordination, enhanced data visibility. | System redundancy, emergency shutoff protocols. | 6-12 months |

| Artificial Intelligence (AI) Optimization | AI analyzes processes and suggests improvements for efficiency. | Optimized operations, reduced waste. | Data security measures, ethical AI guidelines. | 1 year |

| Cloud-Based Automation | Leveraging cloud technology for scalable automation solutions. | Scalability, reduced infrastructure costs. | Data encryption, regular security assessments. | 6-12 months |

Implementing Safety Protocols in Automated Processes

In today's rapidly evolving industrial landscape, implementing safety protocols in automated processes is paramount for ensuring both efficiency and workplace safety. According to the International Federation of Robotics, the global installation of industrial robots is projected to reach 4 million units by 2025, highlighting the increasing reliance on automation. However, with this rise comes the critical need for effective safety measures. A report by the National Institute for Occupational Safety and Health (NIOSH) indicates that a staggering 85% of workplace injuries related to automation stem from insufficient safety protocols. This emphasizes the importance of integrating comprehensive safety systems that can mitigate risks while maintaining productivity.

One effective strategy for enhancing safety is the incorporation of risk assessment frameworks during the design phase of automated systems. Research from the European Agency for Safety and Health at Work (EU-OSHA) reveals that organizations with proactive safety measures can reduce incident rates by up to 45%. By employing regular safety audits and training employees on emergency procedures, companies can foster a culture of safety that not only protects workers but also optimizes operational efficiency. Additionally, leveraging advanced technologies such as AI-driven monitoring systems can provide real-time data on equipment performance, further minimizing potential hazards and ensuring compliance with established safety standards.

Evaluating the Effectiveness of Automation Control Measures

Automation control measures are essential for ensuring that automated systems function effectively while maintaining safety standards. To evaluate their effectiveness, organizations can utilize a variety of metrics, such as performance indicators, downtime analysis, and safety incident reports. By analyzing these data points, businesses can gain insights into the reliability and efficiency of their automation systems. For instance, monitoring how well machines perform their tasks without human intervention can help identify areas where adjustments may be necessary, enhancing productivity and reducing the risk of errors.

In addition to quantitative metrics, qualitative assessments play a crucial role in evaluating automation efficiency. Employee feedback is invaluable, as those who interact directly with automated systems can provide insights into operational challenges and inefficiencies. Implementing regular training and review sessions can facilitate this feedback loop, ensuring that team members understand the automation processes and are aware of safety protocols. Such proactive measures create an environment where automation can thrive while prioritizing human safety and operational efficiency, ultimately leading to improved organizational performance.

2025 Guide: Automation Control Efficiency

This chart presents the effectiveness of various automation control measures in enhancing process efficiency, ensuring safety compliance, and reducing costs among other factors in 2025. The data reflects metrics that organizations can focus on to optimize their automation strategies.

Related Posts

-

Top 10 Benefits of Using Industrial Robots in Modern Manufacturing

-

Understanding Control Systems Automation Types and Their Applications

-

Top Automation Control Trends to Watch in 2025 for Enhanced Efficiency

-

How to Build and Optimize Automatic Systems for Maximum Efficiency

-

Top 10 Control Systems Automation Trends You Can't Afford to Miss

-

Understanding Control Systems Automation for Enhanced Efficiency and Performance